Rainjan Blakers

PVC Stewardship Program continues to drive industry standards 20 years on

The Vinyl Council’s PVC Stewardship Program (PSP) represents an ongoing, voluntary undertaking by the Australian PVC industry to recognise and address relevant environmental, health and safety aspects within the lifecycle of PVC products. PSP Signatories from across the PVC value chain strive to meet a range of stringent commitments in the consumption and manufacturing of raw materials, safe and sustainable use of additives, energy efficiency & greenhouse gas management and resource efficiency.

The PSP was originally developed following a VCA-commissioned CSIRO review into the life cycle of PVC products and potential concerns during 2001, with the review’s initial findings along with extensive stakeholder consultation forming the basis for the program which was launched in 2002. In essence, the program aims to enable all parties involved in the life cycle of PVC, including raw material suppliers, product manufacturers and distributors, to play a role as joint stewards of the safe and beneficial production, use, re-use, and disposal of PVC products.

Now 20 years on, the PSP continues to be a key vehicle to help drive the circular economy for PVC in Australia, with over 50 Signatory companies signed up from across the PVC value chain including market-leaders in the industry. Over the years the program has had a direct impact in helping to inform industry members and stakeholders of best-practice methods and support continued innovation. Achievements include reduced Vinyl Chloride Monomer (VCM) emissions from manufacturing, phasing out lead and cadmium-based additives, improvements in recycling and waste management and avoidance of mercury in upstream processes.

With PSP Signatories required to report annually on their progress in reaching all relevant commitments in the program, results over recent years have continued to drive manufacturing standards to new heights as the PVC industry endeavours to meet increased societal expectations surrounding the environmental and social impacts of products and materials.

Over 50% of Signatories achieved Excellence (full compliance) with PSP commitments in the latest reporting period, while eighty percent achieved at least 80% compliance with program commitments relevant to their business, marking the fourth year in a row that this key program milestone has been reached. Reflecting the industry’s ongoing focus on delivering a circular economy for PVC and avoidance of loss of valuable resources to landfill, one of the key achievements over recent years has been increasing PVC recyclate use, with over 1.6 million kilograms of recycled PVC used by Signatories in the local manufacture of new products in 2021, while a further 1.1 million kilograms of externally sourced recyclate was used in products imported by Signatories.

Over 5 million kilograms of recycled PVC has now been used by PSP Signatories in products since 2016, with recyclate use by Signatories tripling in the last five years alone as more companies look to source and use recyclate, improve circularity and reduce the carbon footprint of their products as part of the program’s resource efficiency commitments.

With leaders from all sectors of the PVC industry included in the list of current PSP Signatories, the program provides businesses from across the value chain with an opportunity to showcase their ongoing commitment to sustainability and implement the necessary frameworks to manufacture and supply PVC as safely as possible. Leading PVC compounder and extruder RBM Plastic Extrusions, a high-performing PSP Signatory since 2016, pinpoint their involvement in the program to the realisation that the market had moved towards a greener approach “with the only real way to move with that being to be part of the program”.

While the broader PVC industry is familiar with the continuous spotlight on meeting relevant sustainability benchmarks, as pressure from environmental and government organisations continues to intensify it has never been more important to demonstrate to customers and external stakeholders that your company is serious about its commitment to sustainable and safe manufacturing. If your business is interested in securing the future viability of your products, become a Signatory of the PVC Stewardship Program and take the next step. Get in touch with the VCA Office today or find out more by clicking here.

Plastics in healthcare products added to Minister’s stewardship priority list for 2022-23

The Vinyl Council of Australia (VCA) welcomes the Federal Labor Government’s addition of plastics in healthcare products to the Minister’s product stewardship priority list for 2022-23, which was announced this week by Minister for the Environment and Water Tanya Plibersek as part of National Recycling Week.

Along with other additions to the priority list of tyres and mattresses, the addition of plastics in healthcare products to the Minister’s stewardship priority list ensures that the makers and importers of these items must take responsibility for the impacts of the products on the environment across their entire life cycle. Going above and beyond simply recycling them, producers and importers of plastic products for healthcare will now have to consider how the development, design, manufacture, import, sale, use and recovery of these materials and products can be adjusted to improve environmental outcomes.

With PVC being the most commonly used plastic polymer across a wide range of applications in the healthcare industry the importance of implementing sound recycling and stewardship initiatives for medical PVC products has been recognised by the VCA for many years, and the addition of plastic healthcare products to the Minister’s priority list builds on the VCA’s existing PVC Recycling in Hospitals (PRIH) scheme which has been successfully running since 2009.

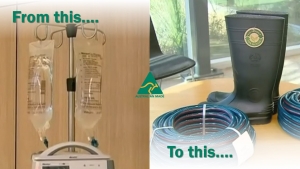

Collaboratively managed alongside program partners Baxter Healthcare and Welvic Australia, the PRIH program helps participating hospitals, medical centres and veterinary practices across Australia to recycle their used PVC medical products including IV fluid bags, tubing and masks, which are collected for re-use in a range of second-life, high-quality PVC products including hosing, mats and gumboots. Despite some logistical interruptions over the course of the pandemic the scheme has continued to expand over recent years to now include over 300 participating hospitals, with an amount of recycled PVC equivalent to over 10 million IV fluid bags collected nation-wide across 2020-21 as part of the program.

With participation numbers constantly growing and recent expansion into more rural areas, recovery rates of PVC in the program are expected to trend upwards as the scheme continues to act as a flagship program with the VCA sharing learnings to assist the adoption of similar PVC medical recycling schemes in Europe, the UK, South Africa, Canada and Thailand.

The VCA has also long-recognised the importance of a collaborative, whole-of-lifecycle approach to product stewardship, and the VCA’s voluntary PVC Stewardship Program (PSP) continues to drive industry standards with over 50 Program Signatories reporting annually on their progress in the safe and beneficial production, use and re-use of PVC products.

The VCA looks forward to supporting the Government’s focus on driving stewardship initiatives and solutions for all PVC items on the Minister’s priority list, to continue to help drive the transition towards national solutions and further innovation in the stewardship of PVC products.

Vinyl Council issues last call for feedback on Best Environmental Practice PVC scheme

The Vinyl Council of Australia (VCA) is holding final consultation and feedback for its updated Best Environmental Practice (BEP) 2.0 PVC product verification scheme, following extensive consultation with stakeholders.

Launched over a decade ago, the BEP scheme remains the most stringent criteria and guidelines for manufacturing PVC with participants required to meet conditions such as emissions targets below regulatory limits, voluntary restrictions on the use of certain additives and stewardship requirements for end of first use of PVC products in Australia.

Under the current BEP scheme, products that are independently verified as being fully compliant with all scheme guidelines are recognised in the GBCA’s product certification scheme for Green Star building rating tools, as well as other public and private procurement policies in Australia.

The VCA also issues a Best Environmental Practice PVC Licence Mark and provides an online register of PVC product manufacturers that are confirmed as meeting the guidelines’ required stringent compliance conditions. BEP accreditation can be achieved by manufacturers not only in Australia but around the world, with PVC products manufactured in Europe, the US and Asia among those having achieved BEP verification.

Updates to the BEP scheme will result in closer alignment of the scheme guidelines with the VCA’s PVC Stewardship Program commitments, which represent an ongoing, voluntary undertaking by companies within the Australian PVC industry to recognise and address relevant environmental, health and safety aspects within the lifecycle of PVC products.

Following an extensive consultation and review period on the scheme with the GBCA and various stakeholders over recent months, the VCA is offering any further interested parties a final chance to provide feedback on the detailed compliance criteria and verification requirements proposed for the updated scheme moving forward. The VCA aims to launch the updated BEP 2.0 scheme criteria and guidelines by late November 2022.

If you wish to provide feedback, please contact the VCA at This email address is being protected from spambots. You need JavaScript enabled to view it. to receive a copy of the proposed changes and other relevant information. All feedback must be received by the close of the final consultation period on Friday 21st October 2022 to be considered.

US EPA lawsuit reinforces the need to showcase strong sustainability and stewardship practices

In the face of the continuous spotlight on the PVC industry globally to meet relevant sustainability benchmarks and consider extended producer responsibility (EPR), the Vinyl Council of Australia (VCA) urges all businesses involved in the Australian PVC value chain to explore the avenues available to safeguard against potential pressures from environmental and government organisations such as those currently taking place in the US.

For those who aren’t aware, in early May 2022 the US Environmental Protection Agency (EPA) published a draft consent decree that it would resolve the Center for Biological Diversity’s (CBD) lawsuit, which alleged that the EPA unreasonably refused to rule on CBD’s 2014 petition to list discarded PVC as hazardous waste under the Resource Conservation and Recovery Act (RCRA).

In 2014, under the Obama Administration, the EPA denied a similar petition from CBD under the Toxic Substances Control Act, but did not act on their subsequent 2014 RCRA petition. After no movement from the EPA in response to CBD’s 2014 RCRA petition to list discarded PVC as hazardous waste, in August 2021 CBD filed a lawsuit against the EPA in which they alleged that there had been unreasonable delay by the EPA to act on the petition. Following the EPA’s consent decree in May 2022, it has been agreed upon by both parties that the EPA make a tentative decision on the listing of discarded PVC as hazardous waste by 20 January 2023 and a final determination by 12 April 2024.

While a granting of the petition by the EPA would likely take years to come into effect in the US and any similar action in Australia would also require long deliberations, in the meantime the question of whether discarded PVC should be treated as hazardous waste will remain active.

As the VCA continues to monitor this case to inform members and industry stakeholders of updates and provide any necessary input, we urge businesses to consider actively pursuing EPR initiatives including opportunities to decrease potential exposure to any eventual classification through implementing sound sustainability and stewardship practices to minimise volumes of discarded and/or waste PVC.

Given that CBD’s petition is not aimed merely at PVC waste generated in the initial manufacturing stage but also that finished materials or products containing PVC are hazardous when discarded, we also recommend due consideration of the flow-on impacts such a classification in the US might have on the recycling of PVC globally and to ensure take-back and recycling schemes are being soundly implemented to maximise re-use of PVC materials and products.

One way in which your business can strongly position itself against any residual flow-back of potential classifications is through joining the VCA’s PVC Stewardship Program (PSP), which is the Australian PVC industry’s voluntary, ongoing commitment to undertaking stewardship practices and addressing relevant environmental, health and safety aspects within the lifecycle of PVC products.

The program includes over 50 Signatories from across the industry who record and report their progress annually in reaching the program’s commitments, with high performing Signatories able to publicly promote their credentials as an industry-leader in sustainability through their involvement in the program. Find out more about the benefits of signing up to the PSP and how your business can become involved: https://www.vinyl.org.au/sustainability/stewardship

Another avenue open to businesses within the PVC value chain to further promote their EPR credentials and re-use of PVC materials is our VinylCycle Label, which represents a collaborative partnership with Good Environmental Choice Australia (GECA) to verify recycled PVC content claims and encourage uptake and innovation relating to PVC recyclate. VinylCycle verification is available to both local and international applicants claiming at least 10% of the PVC compound by weight constitutes recycled PVC, and builds on the VCA’s PSP commitment to encourage the use of recycled PVC in products which has seen PVC recyclate usage in Australia grow significantly since 2015.

As well as providing specifiers, procurers, and consumers with a means of identifying products with genuine recycled content, VinylCycle verification allows businesses to gain recognition for use of PVC recyclate and contribution towards a circular economy for PVC, and importantly provides a framework for management, documentation, and reporting of recyclate use to publicly demonstrate this commitment to industry sustainability. To find out more about the VinylCycle Label and apply, go to: https://www.vinyl.org.au/vinylcycle

As the PVC industry and manufacturing sectors more generally face increasing pressures to exhibit an ongoing commitment to environmental improvements, it has never been more important to take advantage of the opportunities available to your business to showcase sound stewardship and sustainability practices. Membership with the Vinyl Council of Australia and the subsequent access and discounts provided for our range of industry-recognised sustainability programs and product verification schemes will help support a strong EPR stance for your business and a sustainable future for PVC.

Contact This email address is being protected from spambots. You need JavaScript enabled to view it. or click here to find out more about becoming a member of the VCA and the benefits available for your business.

Epworth Richmond leading the way in PVC medical recycling

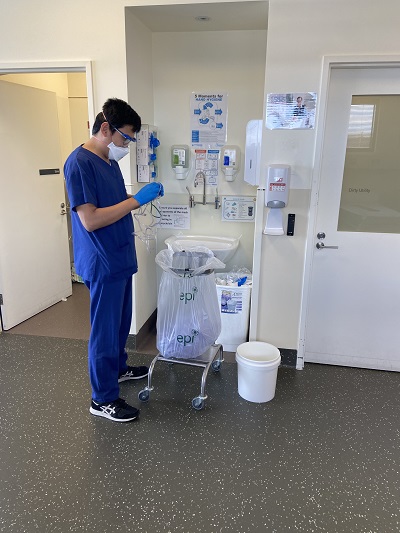

Epworth Richmond has been one of the most consistent high-performing hospitals over recent periods in our PVC Recycling in Hospitals (PRIH) program, with the hospital averaging 250+kg of recycled PVC per month in their collection bins through the first half of 2022. That’s enough to make 2km of recycled garden hose each month! Despite major disruptions to hospital operations during the COVID-19 pandemic in 2020, Epworth recycled almost seven tonnes of PVC, equivalent to 45km of garden hose!

Having been participating in the PRIH program for many years, sustainability has remained a focus at Epworth Richmond. According to Simon Mikedis, Group Sustainability Manager at Epworth HealthCare, interest in the program to recycle used PVC medical devices initially stemmed from a couple of factors. Firstly, the hospital identified PVC was a valuable recyclable resource, however it wasn’t accepted in the general commingled recycling programs due to clinical waste concerns. While PVC items make up a significant share of the hospital’s waste stream, it was being sent to landfill. Secondly, the hospital wanted to address the rising cost of sending waste to landfill and stricter EPA laws around waste prevention and resource recovery, which aligned with a new strategic commitment by Epworth to improved sustainability practices and the circular use of resources.

Since joining the PRIH program, Epworth has focused on education and communication with staff to grow involvement in the program and make PVC recycling such a success. This comprised staff involvement and promotion of the program across the organisation through various sustainability committees, distribution of educational program posters and other materials and acknowledgement of ongoing recycling progress (in association with Baxter Healthcare statistics)

Simon points to the establishment of ‘recycling champions’ in each ward as being integral to the hospital’s success in their recycling efforts. These champions were always available to educate and assist staff in determining the materials permitted in the PVC recycling bins. This level of education plays an important role in helping Epworth reduce contamination from non-PVC waste, which can be a common issue that leaves PVC waste streams unrecyclable if they are co-mingled with non-PVC items which belong in the general waste stream.

As one of the largest hospitals in Victoria, it is great to see the commitment by Epworth Richmond to sustainability and the recycling of used PVC within a circular economy. We look forward to seeing more recycling achievements from them going forward.

To find out more about the VCA’s PVC Recycling in Hospitals program including how your hospital can get involved, go to: https://www.vinyl.org.au/pvc-recycling-in-hospitals

A staff member at Epworth Richmond participates in the PVC Recycling in Hospitals program.

PVC Stewardship Program compliance rises to new heights

The record set for compliance under the Vinyl Council of Australia’s (VCA) PVC Stewardship Program (PSP) has again been broken in the 2021 reporting year, furthering the ongoing streak of sustainable development seen under the program since its inception in 2002. In the latest assessment of 2021 calendar year performance, 26 Signatories demonstrated full compliance with all relevant commitments aimed at furthering the safety and sustainability of the PVC industry in Australia.

“Over half of the current PSP Signatories achieved Excellence in Stewardship, a clear indication that the industry continues to strive for improvement, despite the recent COVID-related challenges,” says Vinyl Council of Australia Industry Sustainability Officer, Alexander Scott.

13 other companies achieved Silver status, ensuring that the key VCA milestone of 80% of Signatories achieving above 80% compliance was once again met. Further growth in scores was achieved by several Bronze Signatories as well, with the VCA hoping to see continued development in the upcoming year.

Continuing the trend from previous years, domestic PVC recyclate consumption by Signatories has once again increased, with over 1,657 tonnes of external recyclate consumed - a 17% increase from 2020 levels. For the first time, recyclate sold to non-Signatories was also measured, with a further 1,473 tonnes reported.

“This represents the continued commitment of the Australian PVC industry to embrace more circular practices and reduce their reliance on raw materials. Reporting on broader industry recyclate consumption also allows the VCA to gather a greater understanding of the current desire for recycled content in local manufacturing,” continues Alexander.

As part of the drive of innovation in PVC recycling, the VCA and Specialised Textile Association’s National Product Stewardship Investment Fund-supported TexBack project has continued to progress. As part of the project, a Materials Flows Analysis on the consumption and waste volumes and locations of PVC-polyester textile products in Australia has been completed, while a world-first separation technology trial and business case and scheme design for a sustainable product stewardship scheme for these materials is currently in progress, with promising results thus far. The project is on track to be completed later this year.

PVC is a particularly versatile and durable polymer, providing safe, functional and affordable solutions across a wide array of vital applications, from delivering drinking water to life-saving medical devices. The PSP program addresses specific, measurable commitments across the life cycle of PVC, including raw materials, manufacturing, supply chains, additives, waste and recycling.

A key component of the program concerns the continued development of the PSP through updated benchmarks or the introduction of new commitments. The Vinyl Council and its Signatories are in strong discussions around the update of the Energy Efficiency and Greenhouse Gas Management commitment to better reflect the rapidly evolving expectations around renewable energy and reducing carbon emissions. In addition, updating requirements within Open Disclosure to include a greater focus on ‘chemicals of concern’ is also likely to be introduced for the next reporting period.

“We would like to congratulate our three newest Signatories, Dincel Construction Systems, IXOM Operations and Plascorp for all achieving at least Bronze status, with IXOM achieving Excellence a noteworthy achievement. We look forward to welcoming more Signatories to the program moving forward and witnessing the sustainable development all Signatories continue to undertake,” concludes Alexander.

Any company manufacturing or supplying PVC, or vinyl, products to the Australian market is welcome to participate in the PVC Stewardship Program.

The 2021-22 Progress Report for the PVC Stewardship Program is now available on the Vinyl Council’s website. Forty-nine Signatories completed the annual assessment, 10 of which were independently verified by EY. A list of Signatories that achieved the Excellence in Stewardship Award (Gold Status) can be found on the Vinyl Council’s website: https://www.vinyl.org.au/signatories.

Vinyl Council of Australia’s PVC Recycling in Hospitals program expands in regional areas

The start of 2022 has seen PVC recycling in healthcare expanding to more regional areas of Australia, including Albany in WA and Rockhampton in QLD, with more than 280 hospitals currently participating in the Vinyl Council of Australia’s initiated program.

Single-use plastics play a vital, life-saving role in healthcare, such as intravenous fluid bags, oxygen masks and tubing. Their ability to be recycled, through schemes like the PVC Recycling in Hospitals program, is diverting increasing volumes of this high-quality, medical grade material from landfill for recycling back into new, useful products. Since 2015, the program has recycled over 545 tonnes of these products – equivalent to over 27 million IV bags.

Despite the impact of the Covid-19 pandemic reducing elective surgery in most states and causing program suspensions in Tasmania, participation in the PVC Recycling in Hospitals program has grown nationally. The latest data shows that over the last two years, more than 60 hospitals Australia-wide have signed up.

Although 2021 waste collection volumes (119 tonnes) were slightly down on the 2020 figures (129 tonnes) due to pandemic disruption, the program continues to play an important role as life starts to return to normality.

Launched in 2013, the PVC Recycling in Hospitals Program collects and recycles non-infectious oxygen masks and tubing and Baxter IV fluid bags from theatres, recovery wards, intensive care units, dialysis and day procedure units. The recovered PVC is reused in a variety of new applications from garden hose to new gumboots.

Although 2021 volumes were down on the previous year due to the pandemic, the 119 tonnes collected were equivalent to 5.95 million IV fluid bags. The Vinyl Council, along with program partners Baxter Healthcare and recycler Welvic Australia, have a target for the program of the equivalent of 50 million IV bags recycled within Australia over a five-year period until 2025.

Reducing contamination and increasing collection at existing hospitals by ensuring the program is implemented correctly will be key focus areas in achieving this target. Separating PVC products from non-PVC products where the waste is generated leads to a higher volume of waste being diverted from landfill. It also produces a higher quality of PVC recyclate by minimising contamination from other materials.

Vinyl Council of Australia Chief Executive, Sophi MacMillan comments: “Our program is playing a leading role in lowering the amount of recyclable single-use plastic used in healthcare going into landfill, thereby reducing its environmental impact.

“We are delighted with the program’s progress, despite the challenging times. We thank everyone for their ongoing involvement and enthusiasm for the program.

“The sustained increase in hospital participation and collection efforts in recent months is encouraging. We hope that with rising participation the 50 million target remains in reach and recycling volumes increase back up to pre-Covid levels again throughout early to mid 2022.”

Since its launch, the Vinyl Council of Australia’s successful medical waste recycling program has inspired similar schemes in eight other countries, such as South Africa, Canada, the European VinylPlus PVCMed initiative and RecoMed in the UK. For more information contact 03 9510 1711, email This email address is being protected from spambots. You need JavaScript enabled to view it. or follow @VCAustralia.

VinylCycle Label Launched to Recognise & Reward Use of Recycled PVC

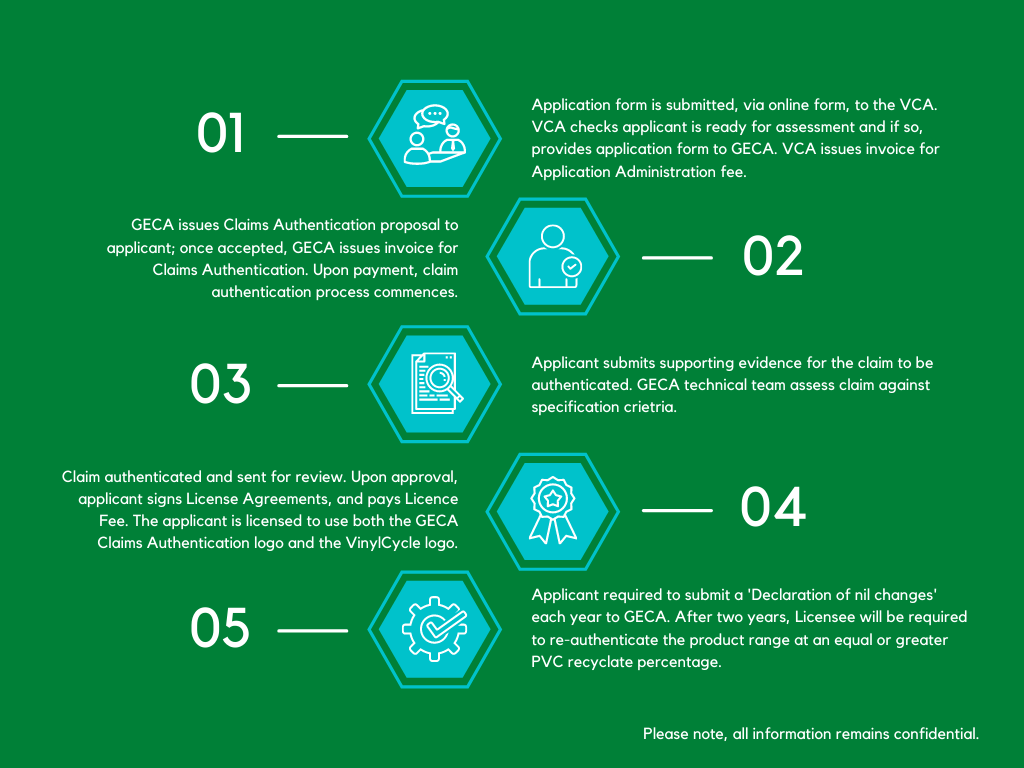

Today marks the launch of the new VinylCycle Label, representing a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encourage uptake of recycled PVC and product design innovation.

The VCA, in conjunction with GECA and with consultation from VCA members and the broader PVC, or vinyl, industry, has developed 'The Specifications for the Verification of Recycled PVC Content Claims in PVC Products'. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC or vinyl. Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in a particular product range. VinylCycle is available to applicants claiming at least 10% of the PVC compound (by weight) constitutes recycled PVC.

"Each step we take towards a circular economy is important for Australia to achieve its ambitious waste reduction targets," says the Hon Trevor Evans MP, Assistant Minister for Waste Reduction and Environmental Management. "The new VinylCycle Label brings the PVC sector one step closer to a circular economy. I look forward to seeing the increasing circularity of vinyls, including the outcomes of the federal government's investments in vinyl recycling made under the National Product Stewardship Investment Fund."

"The VinylCycle Specifications and label are an initiative arising from the Australian industry's PVC Stewardship Program which encourages manufacturers and distributors of PVC products to use recyclate," Vinyl Council CEO Sophi MacMillan explained. "We are pleased to be able to work in collaboration with GECA to authenticate claims and we hope the label plays a role in supporting the Federal Government's ReMade in Australia campaign through providing means for identification and recognition of products with PVC recyclate."

GECA, a purpose-driven not for profit, helping individuals and organisations to make, buy and do better for people and planet, will assess the claim. GECA's Claims Authentication service follows internationally recognised ISO 14021 principles. To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility. GECA is widely respected and recognised in Australia and globally by green building schemes, including Green Star, LEED, IS Rating Scheme, the International WELL Building Institute, NABERS, and many procurement channels in government, education, hospitality, business and the consumer sector.

"We're thrilled to be partnering with VCA to launch the VinylCycle label. Together we aim to recognise those VCA members adopting circular solutions by using recycled PVC in their products. At GECA, our role is to ensure that claims of recycled PVC are transparent and accurate," says Michelle Thomas, GECA CEO.

VinylCycle verification will aid specifiers, procurers, and consumers in identifying products with genuine recycled content to support informed procurement decisions and provide a means for product manufacturers to gain recognition for contributing to the circular economy of PVC and plastics more generally. It further provides a system to help maintain identification of recyclate through the supply chain from waste recovery to product use.

Recycled PVC products may be environmentally preferable based on reduced demand for virgin PVC materials, reduced embodied energy and reduced amounts of PVC waste going to landfill.

Please CLICK HERE to find out more about the VinylCycle specification and claims authentication process.

VinylCycle Label

VinylCycle Label

The VinylCycle Label and verification process represent a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encouraging recycled PVC uptake and related innovation.

The Vinyl Council of Australia, in conjunction with GECA and with consultation from VCA members and the broader PVC industry, has developed 'The Specifications for the Verification of Recycled PVC Content Claims in PVC Products'. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC. Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in the product range produced or imported, and VinylCycle verification is available to both local and international applicants claiming at least 10% of the PVC compound (by weight) constitutes recycled PVC.

GECA, a well-known and trusted ecolabel, will assess the claim. GECA's Claims Authentication service follows internationally recognised ISO 14021 principles. To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility.

Products that have achieved VinylCycle authentication:

Cove Fillet - Armstrong Flooring

The VinylCycle Label builds on our PVC Stewardship Program (PSP) commitment to encourage the use of recycled PVC in products, which has seen PVC recyclate usage grow significantly since 2015. The launch of VinylCycle forms a key part of our ongoing strategy to increase the visibility of the recyclability and actual recycling of PVC, and to recognise companies in the sector that are using recycled PVC.

The use of PVC recyclate has numerous environmental benefits, including reducing the embodied energy of products and diverting waste from landfill. VinylCycle verification will aid specifiers, procurers and consumers in identifying products with genuine recycled content to support informed procurement decisions, and provide a means for product manufacturers to gain recognition for contributing to the circular economy of both PVC and plastics more generally. It further provides a system to help maintain identification of recyclate through the supply chain from waste recovery to product use.

Click here for the Information for Applicants booklet to access further details regarding the application process.

Applications can be submitted via the online form by clicking here.

If your company has any products in its range that are consistently manufactured with recycled PVC, apply for the label now to gain recognition for contributing to the circular economy of PVC!

12 key VCA moments from 2021!

|

While we can't wait to get stuck into 2022, before we get ahead of ourselves we want to reflect on what happened in 2021 and just some of the key achievements we reached across the year. Here are 12 of our biggest moments from 2021!

11. Assisted in the establishment of the Permanent Formwork Industry Council

|