Vinyl Council of Australia’s PVC Recycling in Hospitals program expands in regional areas

The start of 2022 has seen PVC recycling in healthcare expanding to more regional areas of Australia, including Albany in WA and Rockhampton in QLD, with more than 280 hospitals currently participating in the Vinyl Council of Australia’s initiated program.

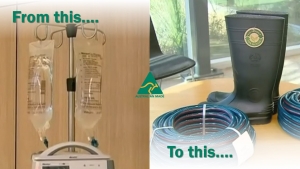

Single-use plastics play a vital, life-saving role in healthcare, such as intravenous fluid bags, oxygen masks and tubing. Their ability to be recycled, through schemes like the PVC Recycling in Hospitals program, is diverting increasing volumes of this high-quality, medical grade material from landfill for recycling back into new, useful products. Since 2015, the program has recycled over 545 tonnes of these products – equivalent to over 27 million IV bags.

Despite the impact of the Covid-19 pandemic reducing elective surgery in most states and causing program suspensions in Tasmania, participation in the PVC Recycling in Hospitals program has grown nationally. The latest data shows that over the last two years, more than 60 hospitals Australia-wide have signed up.

Although 2021 waste collection volumes (119 tonnes) were slightly down on the 2020 figures (129 tonnes) due to pandemic disruption, the program continues to play an important role as life starts to return to normality.

Launched in 2013, the PVC Recycling in Hospitals Program collects and recycles non-infectious oxygen masks and tubing and Baxter IV fluid bags from theatres, recovery wards, intensive care units, dialysis and day procedure units. The recovered PVC is reused in a variety of new applications from garden hose to new gumboots.

Although 2021 volumes were down on the previous year due to the pandemic, the 119 tonnes collected were equivalent to 5.95 million IV fluid bags. The Vinyl Council, along with program partners Baxter Healthcare and recycler Welvic Australia, have a target for the program of the equivalent of 50 million IV bags recycled within Australia over a five-year period until 2025.

Reducing contamination and increasing collection at existing hospitals by ensuring the program is implemented correctly will be key focus areas in achieving this target. Separating PVC products from non-PVC products where the waste is generated leads to a higher volume of waste being diverted from landfill. It also produces a higher quality of PVC recyclate by minimising contamination from other materials.

Vinyl Council of Australia Chief Executive, Sophi MacMillan comments: “Our program is playing a leading role in lowering the amount of recyclable single-use plastic used in healthcare going into landfill, thereby reducing its environmental impact.

“We are delighted with the program’s progress, despite the challenging times. We thank everyone for their ongoing involvement and enthusiasm for the program.

“The sustained increase in hospital participation and collection efforts in recent months is encouraging. We hope that with rising participation the 50 million target remains in reach and recycling volumes increase back up to pre-Covid levels again throughout early to mid 2022.”

Since its launch, the Vinyl Council of Australia’s successful medical waste recycling program has inspired similar schemes in eight other countries, such as South Africa, Canada, the European VinylPlus PVCMed initiative and RecoMed in the UK. For more information contact 03 9510 1711, email This email address is being protected from spambots. You need JavaScript enabled to view it. or follow @VCAustralia.

VinylCycle Label Launched to Recognise & Reward Use of Recycled PVC

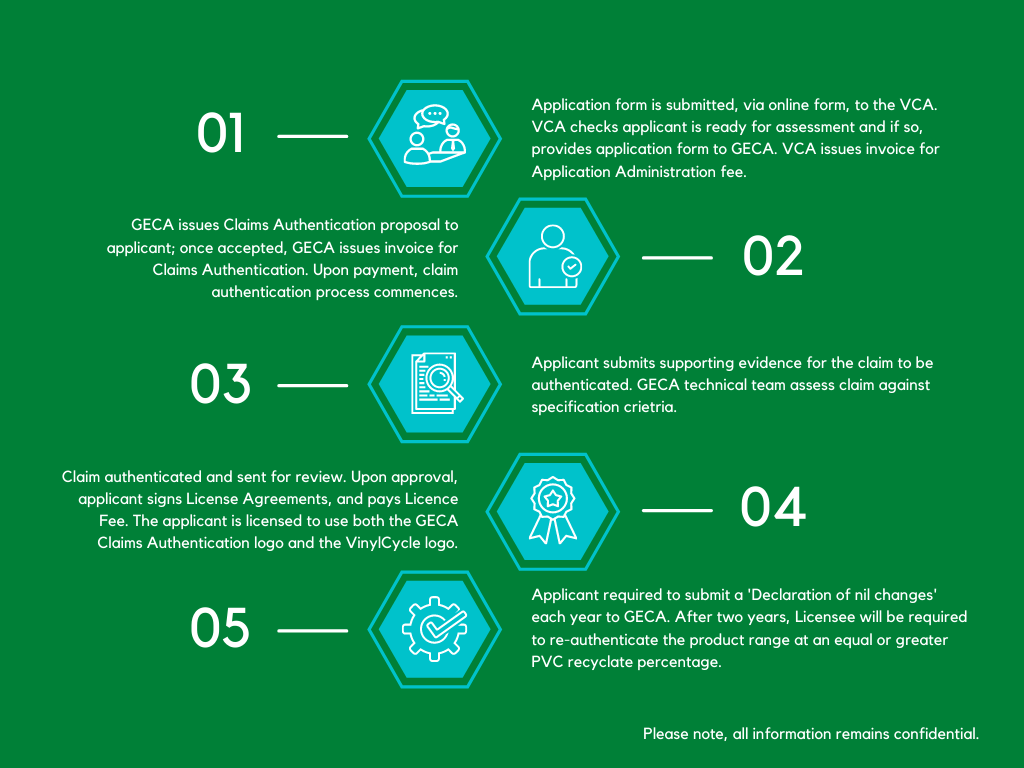

Today marks the launch of the new VinylCycle Label, representing a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encourage uptake of recycled PVC and product design innovation.

The VCA, in conjunction with GECA and with consultation from VCA members and the broader PVC, or vinyl, industry, has developed 'The Specifications for the Verification of Recycled PVC Content Claims in PVC Products'. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC or vinyl. Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in a particular product range. VinylCycle is available to applicants claiming at least 10% of the PVC compound (by weight) constitutes recycled PVC.

"Each step we take towards a circular economy is important for Australia to achieve its ambitious waste reduction targets," says the Hon Trevor Evans MP, Assistant Minister for Waste Reduction and Environmental Management. "The new VinylCycle Label brings the PVC sector one step closer to a circular economy. I look forward to seeing the increasing circularity of vinyls, including the outcomes of the federal government's investments in vinyl recycling made under the National Product Stewardship Investment Fund."

"The VinylCycle Specifications and label are an initiative arising from the Australian industry's PVC Stewardship Program which encourages manufacturers and distributors of PVC products to use recyclate," Vinyl Council CEO Sophi MacMillan explained. "We are pleased to be able to work in collaboration with GECA to authenticate claims and we hope the label plays a role in supporting the Federal Government's ReMade in Australia campaign through providing means for identification and recognition of products with PVC recyclate."

GECA, a purpose-driven not for profit, helping individuals and organisations to make, buy and do better for people and planet, will assess the claim. GECA's Claims Authentication service follows internationally recognised ISO 14021 principles. To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility. GECA is widely respected and recognised in Australia and globally by green building schemes, including Green Star, LEED, IS Rating Scheme, the International WELL Building Institute, NABERS, and many procurement channels in government, education, hospitality, business and the consumer sector.

"We're thrilled to be partnering with VCA to launch the VinylCycle label. Together we aim to recognise those VCA members adopting circular solutions by using recycled PVC in their products. At GECA, our role is to ensure that claims of recycled PVC are transparent and accurate," says Michelle Thomas, GECA CEO.

VinylCycle verification will aid specifiers, procurers, and consumers in identifying products with genuine recycled content to support informed procurement decisions and provide a means for product manufacturers to gain recognition for contributing to the circular economy of PVC and plastics more generally. It further provides a system to help maintain identification of recyclate through the supply chain from waste recovery to product use.

Recycled PVC products may be environmentally preferable based on reduced demand for virgin PVC materials, reduced embodied energy and reduced amounts of PVC waste going to landfill.

Please CLICK HERE to find out more about the VinylCycle specification and claims authentication process.

VinylCycle Label

VinylCycle Label

The VinylCycle Label and verification process represent a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encouraging recycled PVC uptake and related innovation.

The Vinyl Council of Australia, in conjunction with GECA and with consultation from VCA members and the broader PVC industry, has developed 'The Specifications for the Verification of Recycled PVC Content Claims in PVC Products'. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC. Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in the product range produced or imported, and VinylCycle verification is available to both local and international applicants claiming at least 10% of the PVC compound (by weight) constitutes recycled PVC.

GECA, a well-known and trusted ecolabel, will assess the claim. GECA's Claims Authentication service follows internationally recognised ISO 14021 principles. To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility.

Products that have achieved VinylCycle authentication:

Cove Fillet - Armstrong Flooring

The VinylCycle Label builds on our PVC Stewardship Program (PSP) commitment to encourage the use of recycled PVC in products, which has seen PVC recyclate usage grow significantly since 2015. The launch of VinylCycle forms a key part of our ongoing strategy to increase the visibility of the recyclability and actual recycling of PVC, and to recognise companies in the sector that are using recycled PVC.

The use of PVC recyclate has numerous environmental benefits, including reducing the embodied energy of products and diverting waste from landfill. VinylCycle verification will aid specifiers, procurers and consumers in identifying products with genuine recycled content to support informed procurement decisions, and provide a means for product manufacturers to gain recognition for contributing to the circular economy of both PVC and plastics more generally. It further provides a system to help maintain identification of recyclate through the supply chain from waste recovery to product use.

Click here for the Information for Applicants booklet to access further details regarding the application process.

Applications can be submitted via the online form by clicking here.

If your company has any products in its range that are consistently manufactured with recycled PVC, apply for the label now to gain recognition for contributing to the circular economy of PVC!

Vinyl Council secures government funding for new ‘TexBack’ PVC composite recycling scheme

The Vinyl Council of Australia (VCA) and its project partner, Specialised Textiles Association (STA) have secured Government grant funding of nearly $350,000 to further research into the recycling of waste PVC and polyester composite textile products in Australia.

Their TexBack project is one of only 15 successful grant applications (out of a total 190 submissions) and will receive $349,850 from the National Product Stewardship Investment Fund (NPSIF). The Government’s funding program was launched to promote and stimulate shared action for everyday products with a focus on working to reduce waste generation and increased resource recovery.

‘TexBack’ is an industry-driven initiative which aims to steward polyvinyl chloride (PVC)-polyester (PES) composite textile products and waste which are currently not recovered in Australia.

The Morrison Government’s grant will fund the development of the business case for a national product stewardship scheme for textiles such as grain covers, tarpaulins, advertising banners, tents and marquees, roofing and grounds sheets, truck tarps, marine fabrics, swimming pool liners and upholstery fabrics. The project covers a range of activities, including testing of a new chemical separation technology, that will enable the specialised textiles and vinyl sectors to address the growing concerns of waste ending up in landfill.

The NPSIF has projected 1.5 million tonnes of waste to be diverted from landfill through the initiative and will further boost the economy by creating more than 560 potential jobs.

Developing a uniquely Australian solution will pave the way for the establishment of a new, industry-led product stewardship scheme that recovers a complex local waste stream, reprocesses it within Australia and supports the local manufacture of an innovative recycled content PVC building product being developed here, with export market potential. Local markets for recovered polyester will also be sought.

Welcoming the grant, the Vinyl Council of Australia’s PVC Stewardship Manager, Jan van de Graaff said: “TexBack will build on earlier VCA-led research into potential recycling options of PVC coated fabrics conducted over the past four years.

“This grant now gives VCA and STA a real opportunity to collaborate to engage the textile sector in developing a viable scheme for recovery and reprocessing of this waste stream, particularly as there is a potential end-use for the material that will lead to manufacturing of a completely new durable building product in Australia.”

Ana Drougas, Executive Office for the STA said “We are excited to be working with the VCA in an Australian first project to pilot the introduction of innovative and uniquely Australian world-leading PVC Separation technology. We acknowledge and commend the Commonwealth Government for elevating the status of product stewardship as a means of addressing environmental sustainability, growing jobs and the economy.”

In announcing the grant recipients, Minister for the Environment, Sussan Ley said: “We have made it clear that industry needs to take action for their waste. We are investing $10.5 million to seed 11 new and expand four existing industry-led initiatives that will make a practical environmental difference and it is great to see industry respond strongly to our call.”

“Our seed funding, along with the reforms in our Recycling Act, empowers industry and product experts to take more responsibility for their products,” said Hon Trevor Evans MP Assistant Minister for Waste Reduction and Environmental Assistant Minister.

“The grants were six-times oversubscribed which clearly shows the appetite in Australia for putting the power of recycling into the hands of businesses and consumers.”

For more information on the funded product stewardship schemes, visit: https://www.environment.gov.au/protection/waste-resource-recovery/product-stewardship/national-product-stewardship-investment-fund

Vinyl Council of Australia welcomes Federal Government’s A$1 billion recycling plan

The Vinyl Council of Australia welcomes the Federal Government’s commitment of $190 million into a Recycling Modernisation Fund (RMF) that is expected to ‘drive a billion-dollar transformation’ of Australia’s waste and recycling capacity.

The RMF will support innovative investment in new recycling infrastructure to sort, process and remanufacture materials, including mixed plastics.

“We believe this funding is much needed, well targeted and an excellent opportunity to refine the current systems,” says Sophi MacMillan, Chief Executive of the Vinyl Council of Australia. “Australia lags Europe and numerous other countries around the world in terms of sorting, recovery and recycling of mixed plastics and this fund has the potential to help bridge this gap.”

The Vinyl Council has long been calling for this waste to be sorted more thoroughly, enabling plastics such as vinyl to be recycled.

The third most commonly used type of plastic, vinyl (or PVC as it is also known) is used in virtually every sector of the economy from healthcare devices, consumer goods, food and agriculture to education, building and infrastructure. Due to its excellent durability, vinyl is mostly used in long life applications but also some niche packaging applications for its specific functional properties. Although relatively small volumes present in the waste stream annually, these low volumes have often mitigated against investment in developing collection, sorting, and processing infrastructure.

The Vinyl Council believes new investment is needed in a range of systems and technologies to enable recovery, material separation and recycling across our communities and sectors, as well as improved policy drivers that address and incentivize the system holistically from managing waste as a valuable resource to use of recyclate in well-designed, high value, new products.

Since 2002, the Vinyl Council’s PVC Stewardship Program, which commits participating companies to strive for continuous improvement in the environmental footprint of PVC products, has encouraged improved recycling practices for vinyl products in Australia. Signatories have committed to using recycled PVC in new products, particularly in industrial, building and infrastructure products, as well as minimising production wastes and packaging waste sent to landfill.

Annual reporting has found the amount of PVC being recycled by local manufacturing Program signatories grew for a third successive year in 2019 and is now more than double the amount used in 2016.

Ensuring sufficient, consistent local supply of quality recyclate for these manufacturers going forward is a challenge. The Vinyl Council is optimistic that the funding package announced by the Honourable Sussan Ley, Minister for the Environment, will help address this and enable the vinyl resource stream to be retained within the productive economy.

“As our core purpose is to enhance the industry’s opportunities for sustainable growth, we have been working with members and stakeholders to improve PVC recycling,” MacMillan explains. “Our PVC Circularity Taskforce brings together industry and government representatives to drive the industry’s circular economy objectives.

“Working with this forum and with the support of the Federal Government and interested State jurisdictions, we believe we can fast track new technologies that produce suitable clean and sorted PVC for remanufacture locally”, she adds.

Further investment in source separation of wastes and secondary sorting facilities would support the recovery of, for example, rigid PVC packaging materials, which are readily recyclable but often not separated from the co-mingled plastics waste stream.

“We look forward to mobilising and realising these opportunities with interested State Government agencies to improve environmental outcomes and stimulate employment, particularly given the current economic challenges,” MacMillan adds.

“Our members are committed to the circular economy, which has the opportunity to grow substantially if all levels of government harness their purchasing power to support those companies that are active participants in product stewardship schemes and are manufacturing recycled content products.”

Recyclable PVC plays an important technical role in packaging

Versatile and recyclable, PVC (vinyl) provides significant benefits as a specialist packaging material; yet recovering this material for sustainable reuse presents challenges. Sophi MacMillan, Chief Executive of the Vinyl Council of Australia offers some practical solutions.

For more than half a century, PVC or vinyl has been used on a global basis to meet specific functional food and beverage packaging needs. It suits many different food types, offering excellent clarity, unsurpassed physical properties, including heat tolerance, controllable gas and moisture vapour transmission capabilities and exceptional sealing performance.

Most vinyl is used in long life products, particularly building products from pipes, cabling and flooring to window frames and wall profiles, all of which are recyclable. Vinyl used in packaging – such as bottles, thermoformed punnets, pharma blister packs and cling films - represents about 6% of the material’s usage in Australia.

In these applications, vinyl plays an important role in protecting food from contamination and keeping it fresher for longer, while helping to reduce unnecessary food waste. It also protects a variety of high value consumer products, from pharmaceuticals to toys, razors and batteries. In healthcare, vinyl is used in many critical medical items, such as intravenous fluid bags and oxygen hoses. Although a small volume polymer packaging material, it has specific, necessary uses with a relatively low environmental footprint compared to alternatives.

Without doubt, vinyl has revolutionised the way we live our modern lives, helping to deliver safer healthcare, protecting our food and delivering drinking water. Given the high profile of plastics in the media, attention must focus on how we treat this recyclable material at end of life and recover it for beneficial reuse, including energy.

Post-consumer rigid PVC packaging is collected by most local councils around Australia. With existing infra-red sorting technologies, it can be sorted into a defined stream, reprocessed and used as recyclate for use in new products manufactured in Australia. However, at just over 5% of all plastic packaging materials (industrial and consumer) used in Australia, vinyl packaging is only a small proportion of total household packaging waste and is often considered uneconomically viable to sort and recycle.

The 2017-18 recycling rate of PVC packaging waste in Australia is reported to be 7.2% - which is low when compared to the overall average rate of 20.6% for all plastic packaging. (Source - 2017-18 Australian Plastics Recycling Survey published by Envisage Works, 30 January 2019). Nevertheless, clean, separated vinyl waste has value and collection has been actively encouraged by industry.

Clean, separated vinyl waste is relatively easy to recycle, requiring less energy for reprocessing than all other polymers. Using recycled vinyl in new products replaces virgin material and reduces carbon emissions associated with manufacturing virgin vinyl by about 80 to 85%, significantly lowering the carbon footprint of new vinyl products.

While technology exists to identify and sort PVC, few Materials Recovery Facilities (MRFs) are currently operating these systems because of ‘low volumes’. Yet substitution of a small handful of PVC packaging items would almost certainly lead to higher environmental impacts and higher waste volumes in terms of food waste, product damage or alternative non-recyclable composite packaging materials. It will also not remove PVC entirely from the waste stream, so an effective solution to remove PVC ‘contamination’ would be required regardless.

In my view, we need to consider whether the system of use is ‘open’ or ‘closed’ and how these waste plastics can be collected and recovered effectively in both systems for processing into new products, giving it a value as a raw material.

Examples of a ‘closed’ approach might be a major event, an airline or a hospital, where all the plastic waste can feasibly be collected, sorted, segregated and ultimately recycled as single, clean polymer waste streams. An excellent example of PVC packaging being collected and recycled is that of IV bags in healthcare. Schemes in Australia (our PVC Recycling in Hospitals Program), South Africa, Thailand and the UK successfully demonstrate that this material can be separated at waste source, collected and recycled into useful new products.

Conversely, in an ‘open’ system, such as take-away restaurants, all ‘control’ of these waste plastics is lost once single-use plastic walks out the door.

As a material that meets so many of our modern-day needs effectively, we should give careful consideration to how we treat and reuse PVC at end-of-life.

Solution options should cover:

- Separating PVC at source in ‘closed’ consumption systems to achieve a clean waste stream, such as the hospital PVC recycling program. This requires committed collaboration by brand owners, users and the PVC packaging industry to explore the feasibility of establishing collection and recycling schemes, and ultimately, end markets

- Using existing or new techniques and technologies to better separate PVC from co-mingled waste streams at a greater number of Secondary Sorting Facilities around the country, after the removal of higher volume PET and HDPE

- Researching, assessing and supporting the commercialisation and adoption of new technologies – such as chemical separation – to improve production of clean, single material streams for reprocessing

- Developing Waste to Energy projects for co-mingled residues

Demand is growing from manufacturers to increase the use of vinyl recyclate and signatory companies of our long-established PVC Stewardship Program are publicly committed to using recyclate in new products where standards permit.

Through greater collaboration between industry, manufacturers and the wider waste and recycling sector, the vinyl industry can be part of the solution and transform our plastic waste into a sustainable future resource.

PVC Recycling in Hospitals program: 150-hospital target in 2018

The Vinyl Council of Australia aims to expand its successful PVC Recycling in Hospitals program to cover 150 hospitals by the end of 2018.

Since its launch in 2009, the innovative waste management and recycling program has grown to operate in 138 hospitals throughout Australia and New Zealand. It is managed by the Vinyl Council of Australia and its member partners – Baxter Healthcare, Aces Medical Waste and Welvic Australia.

Over the past year, more than 200 tonnes of high-grade PVC waste from hospitals has been diverted from landfill to recycling. This material is redirected to reprocessors in Australia. Australian and New Zealand manufacturers use the recycled polymer in new goods, such as garden hoses and outdoor playground matting.

The program partners are also exploring design of new product applications to accept the growing volume of recyclate generated through the thriving program.

Commenting on their target, Vinyl Council Chief Executive Sophi MacMillan says: “Thanks to great support and enthusiasm from healthcare professionals, the PVC Recycling in Hospitals program is now operating in every state in Australia except the Northern Territory.

“It’s a great example of how the healthcare sector can demonstrate leadership in PVC sustainability and recover high quality material that can be genuinely recycled locally for use in new products. We are currently looking at further end product applications for the recyclate.

“New South Wales is one of our priorities given it only has 11 hospitals participating in the program at the moment. As the state with the biggest population in Australia, the opportunity to grow the program there is really good.”

As part of their drive to encourage greater participation and explain how the program works, Vinyl Council representatives are attending the NSW Nurses and Midwives’ Association Annual Conference in Sydney from 25 to 27 July 2018.

Taking the ‘squiggle’ out of developing recycling solutions

Fostering innovation in recycling and encouraging circularity of materials in the economy is a challenging and complex endeavour, The Vinyl Council has been engaged in such activity for several years, working with members of the vinyl value chain to facilitate solutions to end-of-life PVC products.

Industry Recycling Strategy Manager, Helen Millicer will be presenting on this topic at the 2018 Waste Strategy Summit to be held in Sydney 26-28 June.

On 28 June, in a presentation entitled 'Pilots and Collaborators – taking the ‘squiggle’ out of developing recycling solutions', Helen will share how the Council works to collaborate widely with stakeholders to develop innovative approaches to waste recovery and recycling. As an example, she will outline the challenges and successes of initiating and managing a project to divert a complex end-of-life vinyl product from landfill and find beneficial uses for the raw materials.

Her talk will cover:

• How to implement concrete and effective recycling solutions in organisations

• Understanding the importance of collaboration between industries, organisations and governments in developing recycling strategy

• Learning how to take maximise the chance of success and take the 'squiggle' out of the process

• Some of the exciting possibilities of PVC recycling in Australia

Helen will then participate in a panel session with a number of experts.

Made locally. Recycled locally. PVC Recycling in Hospitals program leads the way in circular economy

The Vinyl Council of Australia wishes to clarify some recent reports about its increasingly successful PVC Recycling in Hospitals program.

Managed by the Vinyl Council of Australia and its member partners in the program – Baxter Healthcare, Aces Medical Waste and Welvic Australia – the PVC Recycling in Hospitals program is a local initiative to redirect high-grade PVC waste from hospitals to local recycling companies to be reprocessed in Australia and sold to Australian and New Zealand manufacturers who produce new, finished products such as garden hoses and outdoor playground matting.

Unlike other commercial and residential programs in Australia and New Zealand, the PVC Recycling in Hospitals program processes and recycles PVC material here in Australia, closing the loop on the manufacture, supply and disposal of PVC products in hospitals.

Thanks to the support and enthusiasm of hospitals, nurses and other healthcare professionals in Australia and New Zealand, the PVC Recycling in Hospitals program has now grown to more than 130 hospitals.

Over the past 12 months almost 200 tonnes of PVC waste from hospitals has been diverted from landfill to recycling.

At a time when residential recycling programs are under enormous pressure due to significant changes to waste management policies in China and its decision to restrict the importation of unsorted waste from other countries, the Vinyl Council confirms its PVC Recycling in Hospitals program remains unaffected by these changes in international waste management. We are proud that our industry program continues to lead by example as a local, innovative waste management and recycling program.

To support the growth of the PVC Recycling in Hospitals program, Welvic made a significant investment in modern recycling equipment last year and has created six new jobs at its Victorian PVC compounding plant.

Baxter Healthcare, a local manufacturer of hospital IV fluids bags, has also invested in education and training in the healthcare sector and provides logistics support.

"We seek to assure the healthcare sector and its staff that the PVC Recycling in Hospitals program is strong and is not affected by China’s ban on unsorted materials. All the medical waste collected under the program has always been, and continues to be, reprocessed and used here or in New Zealand," said Vinyl Council's CEO Sophi MacMillan.

"This example-setting program is growing precisely because it is supported by the local vinyl manufacturing industry and the healthcare sector as product consumers. It is a clear demonstration that circularity within Australia can work."

The Vinyl Council is calling on other industries and manufacturers to support the program and for measures to strengthen the local recycling industry.

"We would like to see greater support and incentives from government to encourage local design and manufacturing of products that use recyclate, to drive demand for recyclate use in Australia,” said Sophi.

“And we’d like policies to encourage procurement of those products that demonstrate they are closing the circularity gap in Australia.”

Research paper on vinyl banner recycling published

A paper by one of the Vinyl Council's research partners, Dr. Sagar T Cholake, Research Associate, Centre for Sustainable Materials Research & Technology, University of New South Wales, has been published in the journal Resources, Conservation and Recycling Volume 136, September 2018 related to the Council's vinyl banner recycling project.

The paper, ‘Cost-effective and sustainable approach to transform end-of-life vinyl banner to value added product’ details a potential, new low-cost solution for waste PVC coated fabrics that does not require the separation of the PVC from the polyester fabric, overcoming a major barrier to recycling.

Testing by the UNSW team indicated that waste PVC-coated banners could be used to fabricate strong and durable composite panels for multiple indoor and outdoor applications and the paper shows one example of final product.

Life cycle analysis, conducted as part of the research, showed that replacing virgin PVC by recycled PVC from banner emits 78% less greenhouse gas emissions (kg CO2 equivalent).

Access this paper through the online journal here.