Making PVC Products

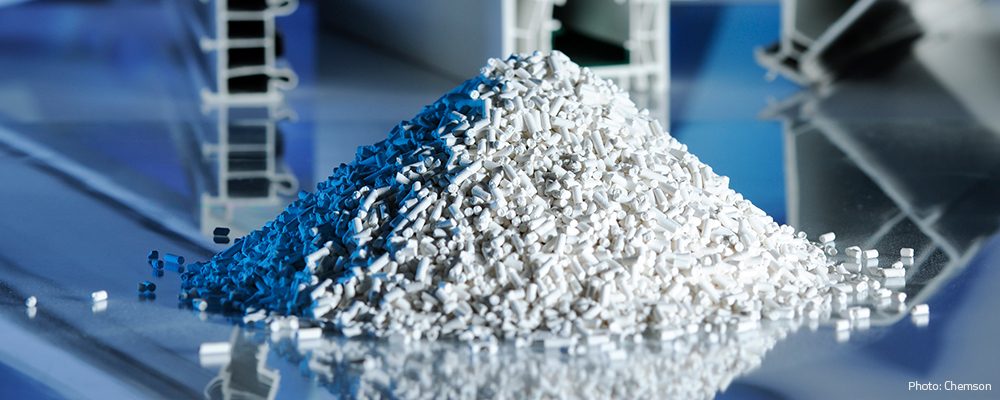

PVC is supplied to factories either as a powder (resin) or, when additives are included, in pellet or granular form as a ‘compound’. The PVC resin or compound is heated and shaped into a final product using a number of different manufacturing techniques.

Heat softens the PVC powder or pellets allowing it to be moulded or extruded into any shape or form. It can be made into pipe, sheet, wire or tape. It can also be used as a coating for other materials, like paper, cardboard or metal.

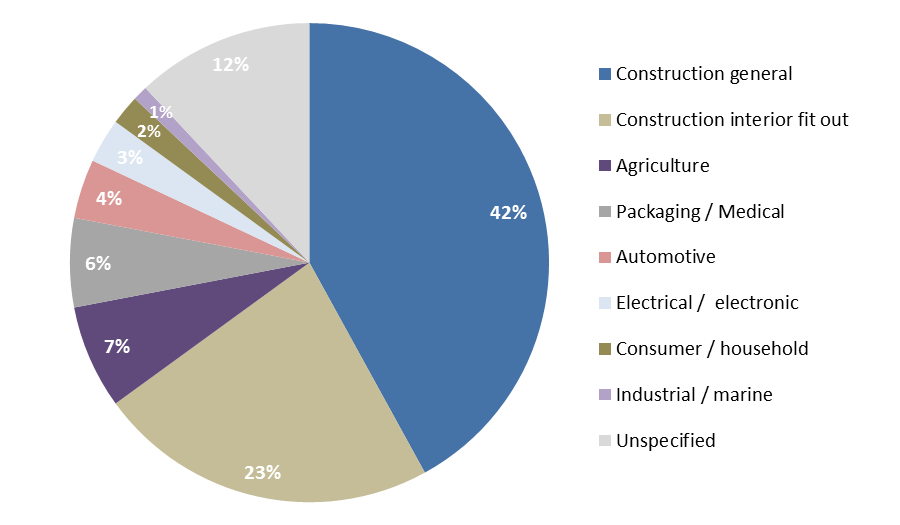

This versatility makes PVC useful across a range of markets and industries including:

- Building and construction.

- Healthcare.

- Automobile, appliance, electronics parts.

- Packaging.

- Upholstery.

- Wire and cable insulation.

- Consumer products.

Common PVC fabrication processes:

| Technique | Process | Products |

|---|---|---|

| Extrusion | Hot, soft plastic is squeezed through a hole of the required dimension, hardening as it cools. | Continuous lengths such as plastic sheet or pipe, window profiles, tile edgings. |

| Injection Moulding | Hot plastic is forced into a mould. When the PVC has cooled the mould is opened to remove the solid plastic object. | More complicated shapes such as pipe fittings, automotive parts. |

| Blow Moulding | Air is blown through a tube of hot plastic, pushing the PVC outwards to the sides of the mould. | Hollow objects such as bottles, jars and buckets. Also, car parts, PVC foam and plastic hardware. |

| Calendering | PVC is squashed between heated rollers to form thin sheets. | Rigid and flexible PVC sheet such as food wrap, flooring and credit cards. |

| Coating | Wire and metal mesh products are dipped in heated PVC then cooled. Coating protects metal from rust and abrasion. | Baskets, cables, coat hangers, tubes. |

Finished PVC can have excellent transparency or it can be made in almost any colour. Blending certain additives with PVC adds properties such as scratch resistance, flexibility and sunlight resistance. Many different mixtures of PVC are made depending on the final purpose.

PVC Use in Australia (based on tonnes of PVC consumed)