PVC’s versatility and sustainability in construction applications is amply illustrated by TechBoard, an innovative product developed by Vinyl Council of Australia member Tech Plas Extrusions Pty Ltd.

A specialist in custom complex extrusions, New South Wales-based Tech Plas was one of the first signatories to the Council’s PVC Stewardship Program established 15 years ago. One of the Program’s commitments is to apply life cycle thinking to the development of new products.

Five years of intensive research and development has gone into TechBoard, a revolutionary new plank designed to last longer and provide much lower life-cycle costs than timber-based planks, with major environmental and economic benefits in the scaffolding and access industries.

As Andrew Swann, Tech Plas Business Development and Sales Manager, puts it: “We have optimised both profile geometry and material choice to produce a long-lasting, lightweight, recyclable, chemically-inert and customisable product that is an ideal timber alternative.”

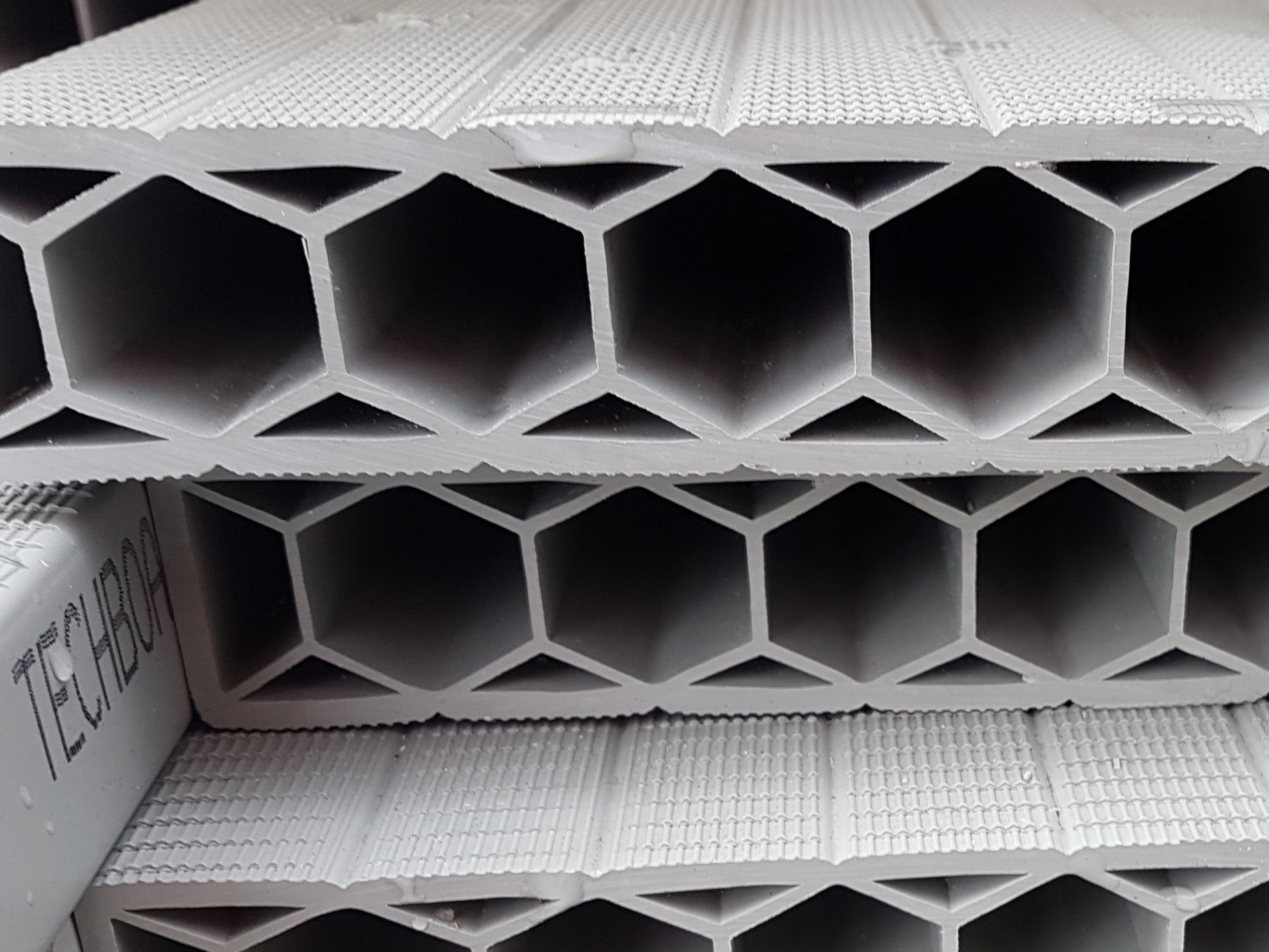

Manufactured with a robust hexagonally-reinforced structure, TechBoards are designed to last so they will not swell, are impervious to weather and water, will not corrode and are non-contaminable. Because they won’t degrade over time, Andrew says, maintenance and storage issues and associated costs are significantly reduced.

The company says they are easier and safer to handle, offering weight savings of up to 40% per plank. Their weather-resistance makes maintenance and storage significantly easier by removing the costly requirements for undercover storage and drying.

Within the Australian and New Zealand scaffold industry the use of timber LVL (Laminated Veneer Lumber) boards is commonplace despite being utilised in environments to which they are not compatible, says Andrew. This leads to nearly 1 million m3 of damaged boards going to waste annually and significantly reduced longevity.

“This is a staggering amount of waste that led us to create our own industry-specific solution with sound environmental credentials.” continues Andrew, “However, introducing a new product for a previously-unexplored market meant we had to overcome some challenges.”

Gaining market entry and acceptance required close industry collaboration – not least in ensuring that TechBoard meets all relevant ANZ and international standards, including AS/NZS 1577:2013.

Industry partnerships, including end users, contractors and specifiers, were crucial in gaining acceptance, such as in the water and wastewater treatment sectors. “Once they’d used TechBoard, they loved it,” says Andrew. Further refinement work followed and Tech Plas developed a number of accessories for the internationally-patented 230mm x 40mm TechBoard. These include safety ramps to prevent trip hazards, plank joiners, end caps and conductive accessories to mitigate static build-up.

TechBoard has applications well beyond the scaffolding and access industry uses, such as retaining walls, noise barriers on freeways, boardwalks and pedestrian access – even planking on submarines.

Andrew added: “We’re proud of TechBoard’s lifecycle savings. Capable of lasting five years, being made from PVC means that it can be readily recycled at end-of-life and used to make new TechBoards.

“After five years of use, we aim to recover the used boards for recycling, thereby reducing environmental impact. Our intended recycling process leaves a clear carbon trail for sustainability.”