VCA and team - Finalists! Vic Premier's Sustainability Awards

Written by Super UserThe VCA is thrilled to announce that thePVC in Hospitals Recycling Program- that started in Melbourne in 2009 and is now going global - has been judged a finalist in the2016 Victorian Premier's Sustainability Awards. This is great timing in the lead up to our openForumon the program running onTues 4 October.

Victorian partners in this world leading initiative, in addition to the hundreds of staff, nurses and anaesthetists across 80 hospitals and healthcare facilities, are:

Western Hospital;

VCA members: Baxter Healthcare, Welvic Australia, and Aces Medical Waste; and

Cryo Grind.

Additional interstate and international partners are Matta Products (NZ), Statewide Waste Services (NSW) and Stateline (Tas).

Winners will be announced in Melbourne on Thurs 20 Oct 2016.

The VCA extends a big thank you and three cheers to all!

Find out how to succeed at PVC Recycling in Hospitals

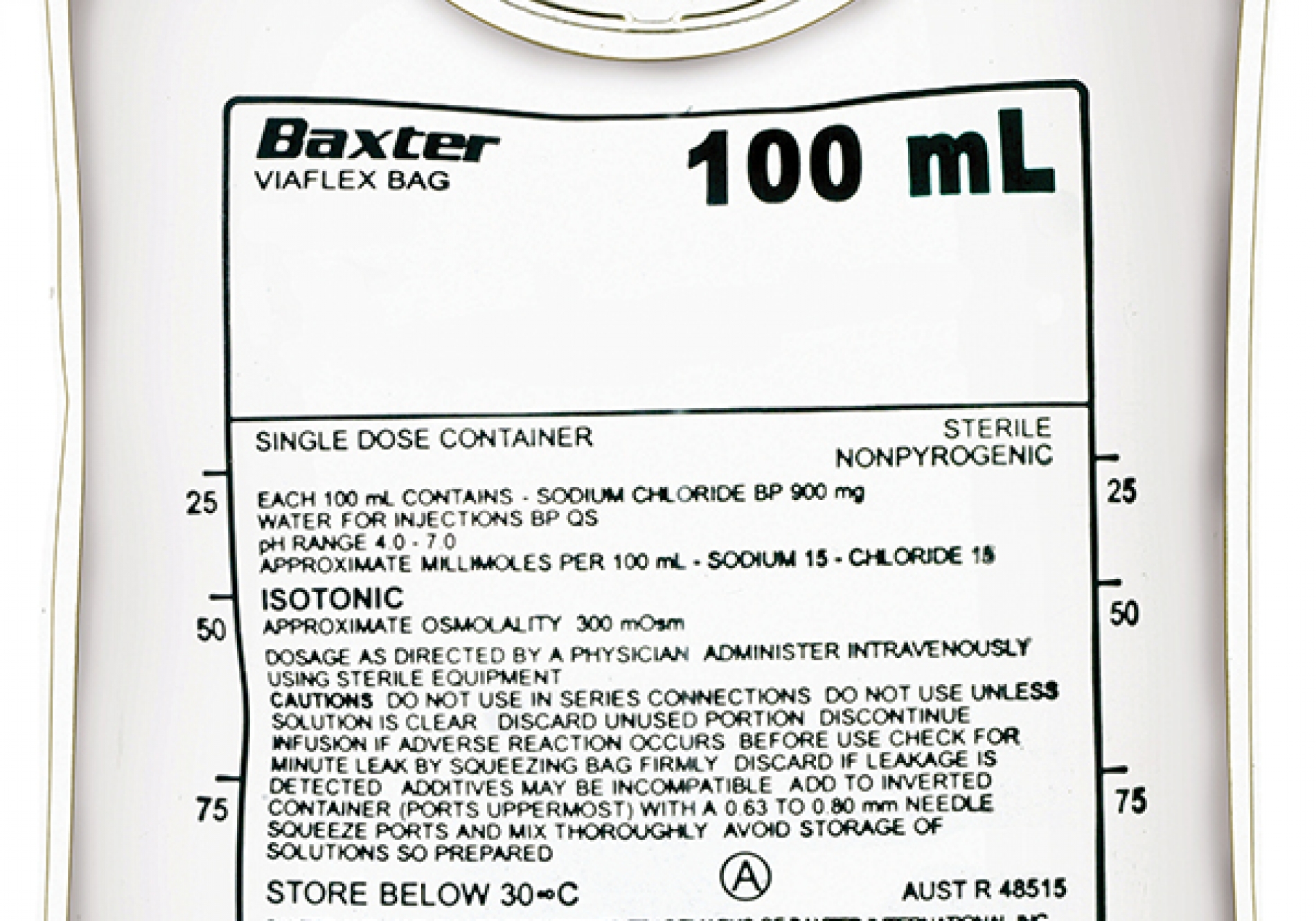

Written by Super User50 million IV bags made from PVC are consumed every year in Australia. They serve an incredibly valuable service to thousands of people undergoing medical care and dialysis. And when they have been used, they should not go to waste.

Such PVC medical products are recyclable and the material is a valued, quality recyclate by donwstream manufacturers.

Today, following growth in a world-leading Australian recycling initative - PVC Recycling in Hospitals - high volume items such as face masks, IV bags and oxygen tubes are being collected and recycled from over 80 hospitals and healthcare facilities in Australia and New Zealand. And the number of participating facilities is growing.

Join our upcomingForumwith expert panel presenters to understand how to implement this program in your healthcare facility and help to take PVC Recycling in Hospitals to the next level.

When: Tues 4 Oct, 8.15-12 noon

Where: Melbourne Exhibition Centre.

More...

Soccer is popular across the world, with prestigious tournaments like the European Cup 2016 viewed by hundreds of millions of people all over the world. Now the Olympic Games are commencing. But greater than the games themselves are the stadia which host them.

A stadium is then not just a venue but adds to the entire “brand-value” package of the city where it is located. It is little wonder then that hundreds of millions are spent on stadia as they are a visible part of the game itself. The Allianz Riviera Stadium, also known as Grand Stade de Nice, was one of the venues of the European Cup 2016. The stadium, designed by Wilmotte & Associés, cost an estimated €245 million. Resembling a flying bird, Allianz Riviera is a magnificent piece of architecture that fits snugly with its surroundings in the middle of the Eco-Vallee, an ambitious long-term development plan for the Plaine du Var centered on sustainability.

One important aspect of stadia are the spectacular roofs, the construction of which creates memorable, emotional connections between the building and its visitors. Roofs that seem to float above the action or that allow looking far into the distance are the crowning achievement of every sports facility.

Plastics, and PVC in particular, have become one of the most widely used materials in building stadia. Flexible PVC is particularly important and can be found in many different applications. Its cost efficiency, durability and light weight make it ideal for roofs and flooring in permanent and temporary sports venues but also in a large variety of sporting goods. PVC membranes add to the modern look of the stadium while protecting the spectators from harsh sunlight and rain. And when it’s time for replacement, PVC can be re-used and recycled into new applications.

The FIFA World Cup 2014 was hosted in 12 different Brazilian cities where seven stadiums were newly built and five were renovated, most of them using virgin and recycled PVC. For example, the petal-shaped roof of the Arena das Dunas in Natal was completely coated with PVC on one side. The Arena Pantanal, which replaced the Stadium Governador José Fragelli in Cuiabá, used a fire-resistant PVC membrane on the inside as well as a waterproof PVC membrane on the outside of its roof. PVC membranes were chosen as part of an airy architecture making use of natural light and cross ventilation to save energy.

Olympic Games always require extensive construction work for the host city. A little known aspect is the extent of recycled PVC in stadium construction now. Recognising the great potential of PVC, the Commission for Sustainable London 2012 even established a dedicated policy for its use - a major contrast to the Sydney 2000 Games, where policies were set to avoid the use of PVC.

Material used in constructing various temporary sports and games facilities for the London Olympics were eventually recycled and found their way even into primary schools as flooring systems!

The recycling of vinyl roofs starts with the removal of the old membrane from the facility. The membrane is then packaged and consolidated and shipped to a facility where it is processed into a form that can be reintroduced into the new product manufacturing stream. Vinyl is an excellent candidate for recycling because the old roofing material is easily introduced into the raw material base for the manufacturing of new roofing membranes and accessories.

Clearly, the preference for PVC and the sheer amounts currently in use for stadium construction affirms the successful path to sustainable development the PVC industry has taken. And is a testament to the inherent qualities and robustness of the material.

Source: European Council of Vinyl Manufacturers, August 2016

The Vinyl Council has updated its industry strategy aimed at facilitating growth in sustainable PVC recycling practices in Australia.

Developed through consultations with members, industry and government, and at the PVC ReSource Summit held in late 2015, the strategy will direct future actions of the Vinyl Council and the sector.

PVC - the third most commonly used polymer in Australia - is recyclable, however, results show that only low volumes of PVC wastes are recovered, largely because most PVC is used in durable products, and less in packaging (which is where most waste and recycling policies and resources are focussed).

The VCA estimates around 66,900 tonnes ofrecyclablePVC product goes to landfill each year. This is wasted material that could be reprocessed into new quality product by Australian workers and firms, improving Australian productivity, economy and the environment.

The VCA and its members are committed to advancing PVC recycling and reprocessing. The updated industry strategy aims to address barriers, to share knowledge, data and expertise and to encourage innovation of reprocessing, product design and recycling capability.

Key elements in the 2016 Strategy

There are six parts to the strategy and three especially form the foundation:

- Data and information. More data and knowledge are required for effective recycling of PVC.

- Collaboration between willing partners to drive change. Systemic change requires partners working together, and strong PVC reprocessing capability is required in all key States.

- End markets, without which there is no viable recycling practice. This requires building connections between demand and supply, development of appropriate recyclate-absorbing products and encouraging substitution of virgin or other less sustainable materials.

The VCA has established successful vinyl recylcing programs including the PVC Recycling in Hospitals program which is now in place at over 60 Australian hospitlas. The VCA thanks all those who contribute to the success of PVC recycling in Australia and looks forward to working with many to achieve the actions for improved results for Australia's recycling rate, productivity and manufacturing future.

For more detail on the Strategy contact the Vinyl Council's This email address is being protected from spambots. You need JavaScript enabled to view it..