VCA member a winner of European innovation award

Written by Super UserVCA member a winner of European innovation award

Vinyl Council of Australia member, Chemson Pacific Pty Ltd has taken home the 2016 INOVYN Gold Award for Innovation with Vinyls for its project to formulate and engineer 3-D vinyl to be used as a cost effective and sustainable raw material in 3-D printing.

Chemson's project was researched and conducted in Australia and launched at our conference, PVC AUS 2016, in May. 3-D VinylTM compound has global application.

Managing Director of Chemson Pacific, Greg Harrison, on receiving the award at a special ceremony held at ‘K2016’, Europe's flagship fair of the plastics and rubber industries, said: “It's really an honour to have won this award and to be recognised by INOVYN for our contribution to PVC. We have a great belief in sustainability. We believe that we will now take PVC into the new world of Advanced Manufacturing. It's definitely an opportunity for us, and it's a sustainable opportunity.”

INOVYN Awards judge Dr. Keith Watkinson commented on 3-D VinylTM saying “This development opens up many exciting opportunities for PVC in additive manufacturing. The unique properties of UV and fire resistance will permit many new products to be created.”

Chemson Pacific was a founding member of the Vinyl Council of Ausutralia in 1998 and has been a signatory to the PVC Stewardship Program in Australia since it began in 2002. Based at Eastern Creek, NSW the company manufactures stabilisers for the local PVC manufacturing industry.

The INOVYN Awards 2016 attracted entrants from around the world including manufacturers; distributors; product specifiers; architects and designers; students; academics and research organisations. More than 70 projects were competing for the top accolades in three award categories: Innovation; Sustainability; and Industrial Design.

Winner of the ‘Sustainability’ category was UK-based Axion Consulting for its RecoMed PVC take-back scheme that recycles PVC used in healthcare. This scheme was initiated and developed after learning of the PVC Recycling in Hospitals program the Vinyl Council had initiated in Australia.

The winners in each award category were selected by an independent panel of expert judges comprised leading figures from the world of sustainable development; materials science; life-cycle assessment; industrial design and architecture; and the media. For more information visit https://www.inovyn.com/news/inovyn-awards-2016--winners-highlight-continued-diversity-of-innovation-with-vinyls/

K2016 is being held in Düsseldorf (Germany) until 26 October 2016.

It’s time to make the change to uPVC windows

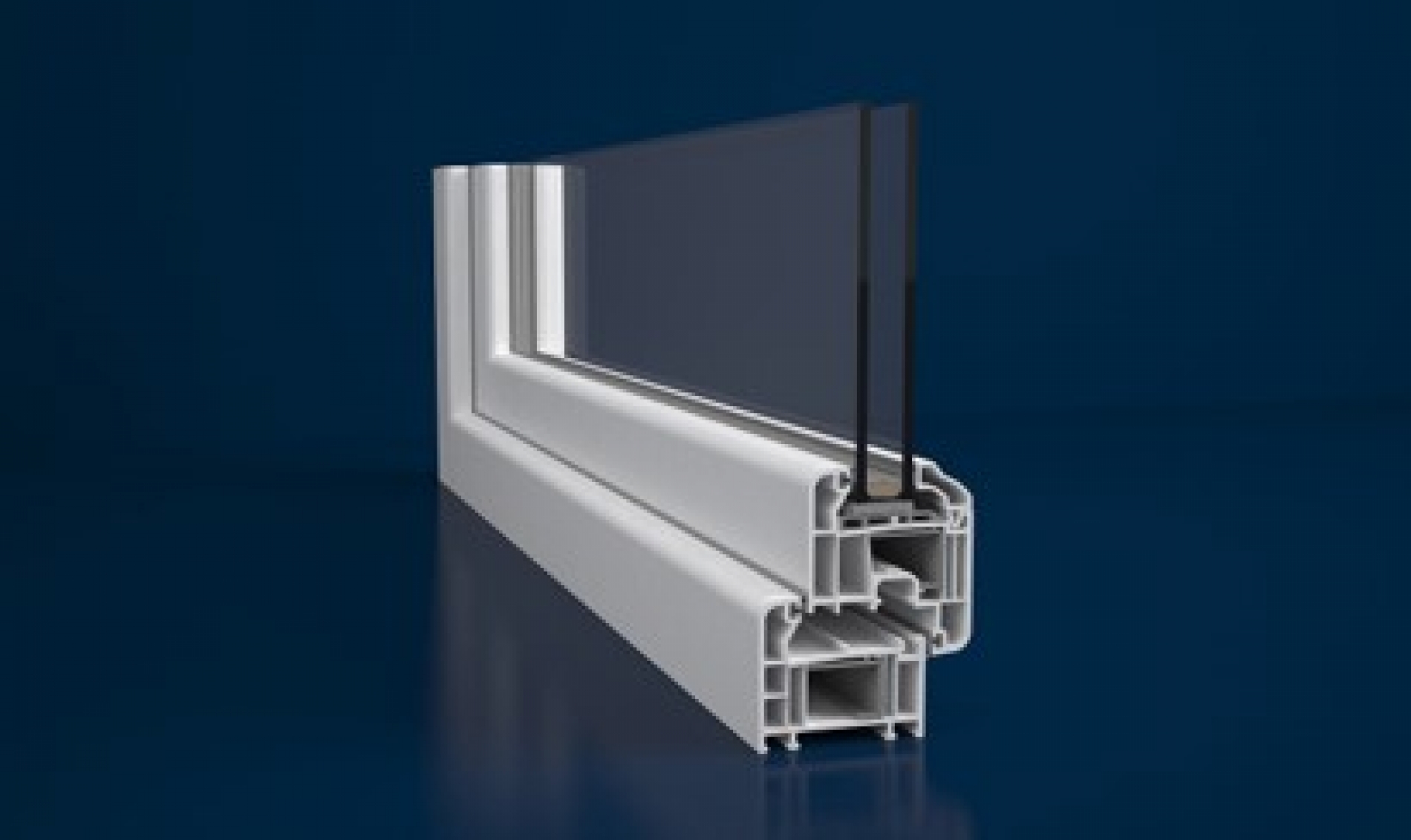

Although we have seen a steady increment over the past five years, the uPVC window sector in Australia currently represents just 4-5 percent of the total window market here. Nevertheless, there is an expectation from most quarters of the industry that uPVC windows will become increasingly popular, just as they have in other major regions such as the US and Europe.

During his recent visit to Australia, we talked to Dr Peter Mrosik, owner/CEO of Profine GmbH – one of Europe’s leading producers of uPVC window profiles – for his views on what is holding back this market and what we might learn from the experience of other countries.

Peter explained that education of Australian consumers to understand that double-glazed uPVC windows offer benefits unmet by standard aluminium windows is paramount. They are still a relatively unknown product here.

It is also important, he said, to educate specifiers such as architects, particularly to raise awareness of the existence of high UV resistant profiles formulated for the Australian and other high UV markets. Many architects and designers are unsure about the suitability and benefits of uPVC windows in this country and the types of buildings and locations they are ideally suited to. Yet they are long lasting, low maintenance, resistant to salty coastal environments and can even be used in bushfire prone areas. We hope that theuPVC Window Alliancewebsite is a start in this process of sharing information.

Thirty – 40 years ago, the US and European markets saw significant and rapid growth of uPVC windows as manufacturers of aluminium products switched to uPVC, particularly in the face of government-mandated building energy efficiency requirements. Today, uPVC accounts for roughly 70 percent of all window sales in the US nationally; in Europe it is 55 percent. These changes were driven by preference for low maintenance, well insulated windows at a time of increasingly stringent building energy performance standards.

“uPVC windows are simply a better product,” Peter explained. “The market has started to move in Australia as it has in other countries, like China and India.”

However, Australia still lags major overseas markets when it comes to mandatory energy efficiency performance standards and codes. Even China, Peter pointed out, has government policies that are driving use of higher performing windows. Recognising the importance of energy efficient door and window products, Chinese energy codes set energy efficiency requirements for doors and windows, which has helped to drive take-up of higher performing products. For example, the maximum U-value permitted for windows in the country’s severe cold region has been 2.0 W/m2K since as far back as 1995! In 2010, this was reduced to a maximum of 1.5 W/m2K, raising the bar again on window performance.

Meanwhile, in Germany where Peter’s based, the government is moving new-build houses closer to the Passivhaus standard as its overall building energy policy moves in line with the nearly-zero energy standard required by the European Buildings Directive.

Although rates of use of insulated or double-glazing are growing in Australia, there is a lack of building energy policy drivers to encourage use of higher performing windows. As ourrecent articleshowed, of the Window Energy Rating System (WERS)-rated residential window products offered in Victoria, considered a heating climate, almost half have U values of 4 W/m2K or more. Less than 3 percent of products offered have U values under 2.0 W/m2K.

The most energy efficient window frame materials are those that will not transfer heat and cold, such as uPVC.

The change has started. Be part of it!

More...

The Vinyl Council of Australia and the Outdoor Media Association (OMA) are looking to create a more sustainable future for Australia's billboard industry by showcasing ways to recycle PVC billboard skins and convert them into useful products.

At an event on 11 October 2016, hosted by the OMA in Sydney, participants will learn about the cooperative research work currently underway with industry and research students at the Universities of Monash and NSW aimed at exploring viable, billboard waste recovery and reprocessing practices and the development of product and material prototypes made from the waste.

The project has been funded by the NSW Environment Trust, as part of NSW EPA’s Waste Less Recycle More strategy. Each year, large amounts of billboard skins go to landfill at a significant cost to businesses and the environment.

The Billboard Vinyl Recycling Forum in October will discuss current progress in developing solutions to enable these valuable materials to enter the circular economy.

Further investment in PVC reprocessing technologies in Victoria

Written by Super UserVinyl Council member and PVC Stewardship Program signatory, Welvic Australia has been awarded funding from the Victorian Government and the Australian Packaging Covenant to invest in innovative technology to divert PVC from landfill.

This matching funding will enable Welvic to expand and improve production to reprocess between 800-1000 tonnes of PVC a year. This will mean they will become one of the largest reprocessors and recyclers of PVC and along with other businesses, will ensure Victoria is the powerhouse in PVC recycling in Australia.

Welvic already receives common PVC items such as medical IV bags and they are exploring new opportunities such as advertising banners, and this will expand once the new plant is commissioned. High quality PVC recyclate is expertly mixed with compounds and can be returned for its original use or used in a large array of new product, such as industrial hoses and mats.

"This is a great example of what we can achieve through innovation and technology - Welvic can take what was once 'waste' and turn it into something valuable and new," Sustainability Victoria CEO, Stan Krpan said.

"It's particularly valuable in recycling flexible plastics, which is one of six priority materials identified in the recently released Victorian Market Development Strategy for Recovered Resources.

Welvic Director, Matthew Hoyne said "PVC recycling deserves to have a strong future in Australia. This grant is a good step forward improving Australia's capacity to reprocess a wide array of PVC products so we can deliver and support manufacturers with high quality recyclate and help them improve their competitive position in local and international markets."

VCA and team - Finalists! Vic Premier's Sustainability Awards

Written by Super UserThe VCA is thrilled to announce that thePVC in Hospitals Recycling Program- that started in Melbourne in 2009 and is now going global - has been judged a finalist in the2016 Victorian Premier's Sustainability Awards. This is great timing in the lead up to our openForumon the program running onTues 4 October.

Victorian partners in this world leading initiative, in addition to the hundreds of staff, nurses and anaesthetists across 80 hospitals and healthcare facilities, are:

Western Hospital;

VCA members: Baxter Healthcare, Welvic Australia, and Aces Medical Waste; and

Cryo Grind.

Additional interstate and international partners are Matta Products (NZ), Statewide Waste Services (NSW) and Stateline (Tas).

Winners will be announced in Melbourne on Thurs 20 Oct 2016.

The VCA extends a big thank you and three cheers to all!

Find out how to succeed at PVC Recycling in Hospitals

Written by Super User50 million IV bags made from PVC are consumed every year in Australia. They serve an incredibly valuable service to thousands of people undergoing medical care and dialysis. And when they have been used, they should not go to waste.

Such PVC medical products are recyclable and the material is a valued, quality recyclate by donwstream manufacturers.

Today, following growth in a world-leading Australian recycling initative - PVC Recycling in Hospitals - high volume items such as face masks, IV bags and oxygen tubes are being collected and recycled from over 80 hospitals and healthcare facilities in Australia and New Zealand. And the number of participating facilities is growing.

Join our upcomingForumwith expert panel presenters to understand how to implement this program in your healthcare facility and help to take PVC Recycling in Hospitals to the next level.

When: Tues 4 Oct, 8.15-12 noon

Where: Melbourne Exhibition Centre.