VinylCycle Label

VinylCycle Label

The VinylCycle Label and verification process represent a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encouraging recycled PVC uptake and related innovation.

The Vinyl Council of Australia, in conjunction with GECA and with consultation from VCA members and the broader PVC industry, has developed 'The Specifications for the Verification of Recycled PVC Content Claims in PVC Products'. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC. Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in the product range produced or imported, and VinylCycle verification is available to both local and international applicants claiming at least 10% of the PVC compound (by weight) constitutes recycled PVC.

GECA, a well-known and trusted ecolabel, will assess the claim. GECA's Claims Authentication service follows internationally recognised ISO 14021 principles. To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility.

Products that have achieved VinylCycle authentication:

Cove Fillet - Armstrong Flooring

The VinylCycle Label builds on our PVC Stewardship Program (PSP) commitment to encourage the use of recycled PVC in products, which has seen PVC recyclate usage grow significantly since 2015. The launch of VinylCycle forms a key part of our ongoing strategy to increase the visibility of the recyclability and actual recycling of PVC, and to recognise companies in the sector that are using recycled PVC.

The use of PVC recyclate has numerous environmental benefits, including reducing the embodied energy of products and diverting waste from landfill. VinylCycle verification will aid specifiers, procurers and consumers in identifying products with genuine recycled content to support informed procurement decisions, and provide a means for product manufacturers to gain recognition for contributing to the circular economy of both PVC and plastics more generally. It further provides a system to help maintain identification of recyclate through the supply chain from waste recovery to product use.

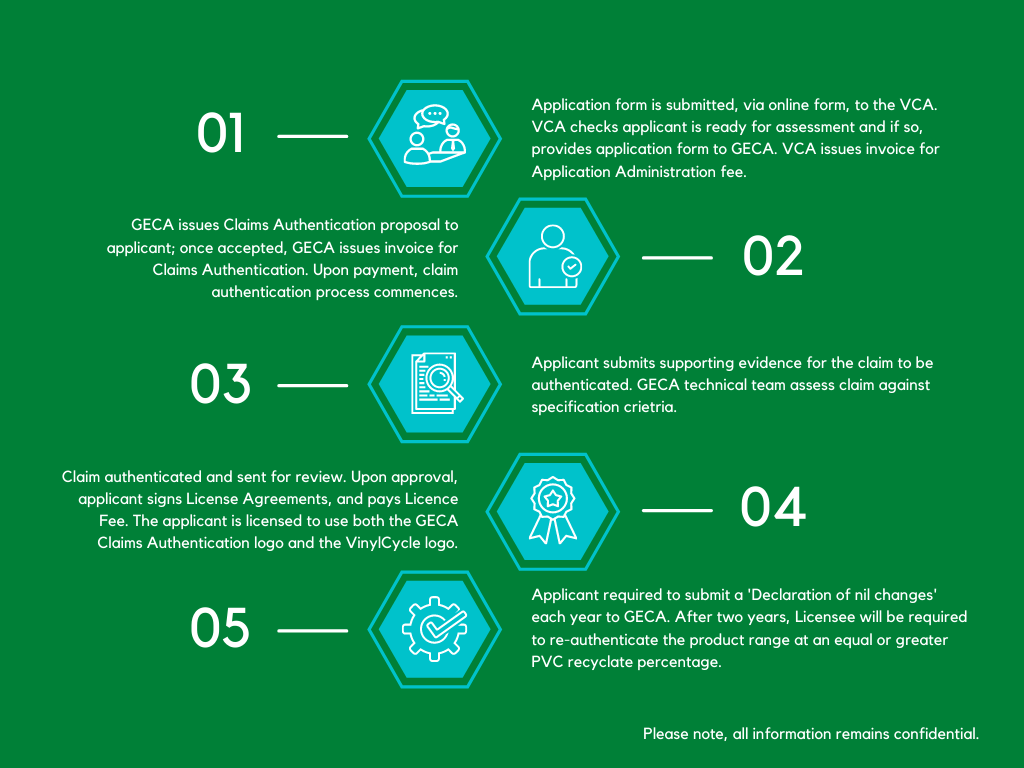

Click here for the Information for Applicants booklet to access further details regarding the application process.

Applications can be submitted via the online form by clicking here.

If your company has any products in its range that are consistently manufactured with recycled PVC, apply for the label now to gain recognition for contributing to the circular economy of PVC!

Partnerships aid progress in vinyl sustainability

Global vinyl industry partnerships are driving progress in the sustainability of the Australian PVC industry, resulting in the creation of successful initiatives such as best practice manufacturing, product stewardship and recycling.

Sophi MacMillan, Chief Executive of the Vinyl Council of Australia and a member of the Global Vinyl Council, believes that partnership is ‘absolutely integral to the work that we do as an association focused on sustainable development of the industry’.

During a panel discussion at the recent VinylPlus Sustainability Forum 2019 held in Prague, Czech Republic, Sophi emphasised the importance of partnerships for sharing knowledge, experience and strategies with experts from all the regions of the vinyl world.

“Attending the Global Vinyl Council meeting and the European Vinyl Sustainability Forum provides a great opportunity to build connections across the industry beyond Australia and our region. For the Australian vinyl industry, which is a small market, partnerships have been essential to us to move forward, to be able to tap into the knowledge of people, particularly in Europe and the US.

“It’s these connections that help us to develop our voluntary, industry PVC Stewardship Program and our initiatives around recycling, as well as sharing ideas and best practice.”

The Vinyl Sustainability Forum, organised by VinylPlus, the voluntary sustainable development commitment of the European PVC industry, attracted more than 170 participants from 32 countries to share further progress towards advancing the sustainability of the industry and its products.

Sophi continued: “Europe’s VinylPlus program is a leader in striving towards sustainable goals across the whole vinyl industry supply chain. Here at the Vinyl Council of Australia we follow in their footsteps with our own PVC Stewardship Program that has driven continual improvement in the vinyl industry for 17 years. We see stewardship as being a shared responsibility, so it is about working with, not just industry members, but also stakeholders - particularly government and NGOs - and trying to establish constructive partnerships.

“It’s about being aware of different epistemologies – different ways of knowing – which can help us to remove blinkers, to understand and characterise issues and develop paths to address them.”

Nowhere is this more important than in addressing the need for the industry to engage in the circular economy. Sophi highlighted their successful PVC Recycling in Hospitals Program, which now has 175 hospitals across Australia and New Zealand participating in the collection of PVC medical products for recycling back into new products, and through collaboration, is being implemented in other countries such as South Africa, the UK and Thailand.

In Australia, partnering with medical devices manufacturer Baxter Healthcare, PVC recyclers, medical waste collection companies, state governments and health authorities has been essential to developing and successfully delivering the program.

Sophi added: “Collaboration with the nurses and midwives’ union has also been very helpful in terms of finding pathways to engage nursing staff and to develop training on which medical products are recyclable under the program.”

A further example was given of the Council’s partnerships with academia such as Monash University and manufacturers in the development of product concepts for vinyl recyclate.

The Vinyl Council would like to see such wider collaboration form between stakeholders, particularly end-user brands, in the broader plastics packaging space.

“By working together, we have more knowledge, more ideas and are better equipped to find solutions to seemingly intractable problems.”

The recyclability of PVC packaging in Australia

PVC (vinyl) packaging - designated by the Plastics Identification Code number 3 - is recyclable.

Vinyl has long been used on a global basis to meet specific functional food and beverage packaging needs. It offers users excellent clarity, unsurpassed physical properties including heat tolerance, controllable gas and moisture vapour transmission capabilities and exceptional sealing performance. Unlike many other materials, Vinyl can be formed into a myriad of complex and functional forms to suit many different food types.

Most vinyl (>85%) is used in long life products, particularly building products, such as potable water pipe, conduit, cabling, flooring and window profiles, all of which are also recyclable in Australia. Vinyl used in packaging represents approximately 5 percent of the material’s usage in Australia.

Vinyl packaging is commonly used for clear, handled bottles such as for cordials; clamshells to protect fresh fruit, vegetables, bakery and other fresh food items; and as very light gauge film for wrapping and protecting fresh meat, produce, dairy and deli products. Vinyl plays an important role in keeping fresh food fresh, and in turn benefits consumers by protecting the fresh food from early spoilage or other forms of undesirable food contamination.

Vinyl is also used as secure blister packaging for high value products such as pharmaceuticals, batteries, razors, toys, and an array of other consumer products. An important material for healthcare, Vinyl is used in many critical medical items, such as intravenous fluid bags and body fluid hoses, used in the delivery and management of blood and other fluids in operating theatres and similar critical care situations.

Post-consumer PVC packaging is collected by most local councils around Australia and by industry directly from the healthcare system. It can be sorted into a defined stream, can be reprocessed and used as recyclate for use in new products manufactured in Australia. However, at just over five percent, vinyl packaging is only a small proportion of all plastic packaging materials (industrial and consumer) used in Australia.

The 2017-18 recycling rate of PVC packaging waste in Australia is reported to be 7.2% - which is low when compared to the overall average rate of 20.6% for all plastic packaging. (Source - 2017-18 Australian Plastics Recycling Survey published by Envisage Works, 30 January 2019).

Clean, separated vinyl waste has value and collection is actively encouraged by industry.

Rigid vinyl packaging

Rigid vinyl packaging such as bottles and thermoformed packaging is recyclable when collected from kerbside and sorted from other polymers and packaging materials. Most councils around Australia have included these products in collections for many years.

Post-consumer vinyl bottles are separated out where manual sorting systems operate at Materials Recovery Facilities (MRFs) and sent to recyclers. The Vinyl Cycle bottle recycling program that operated for many years (until 2012) demonstrated that a recycling rate of over 50% was achievable when vinyl bottles were manually sorted for recycling, however very few MRFs operate such systems today.

Optical sorting technologies exist based on Near InfraRed cameras that can identify polymer types, including vinyl, and colours (except black). These achieve high purity streams, generally 93-96% for most polymers. In Australia, however, use of such technologies has largely been limited to identifying the dominant two packaging polymers only – PET and HDPE – despite local demand for recovered vinyl for remanufacturing within Australia.

Post-industrial rigid vinyl packaging materials, such as thermoforming web scrap, is sought after by recyclers for use in other products.

Flexible vinyl packaging

A successful program currently operates across Australia’s healthcare sector. The ‘PVC Recycling in Hospitals’ scheme operates in over 170 healthcare facilities in Australia and New Zealand and collects approximately 15-20 tonnes a month of vinyl intravenous bags, tubing and oxygen masks. This material is reprocessed locally into new, long-life products. The success of the program is, in part, due to the separation at source of the vinyl products, reducing contamination from other polymers and materials.

Unfortunately, there is little collection and recycling of post-consumer films and food wrap, regardless of polymer type. This is due to a number of reasons - high contamination from dirt, food waste and other non-plastic materials and contaminants; the wide range of polymers and other materials used to manufacture films, such as mono layer, multilayer and mixed polymer films; and the risk of films generally entangling and damaging traditional processing equipment at the MRF.

Nevertheless, the vinyl film industry in Australia has taken appropriate actions to reduce raw material use through down-gauging films and continually seeking ways to reduce the life cycle footprint of these products by way of material selection.

Benefits of sorting and recycling vinyl packaging

Clean, separated vinyl waste is relatively easy to recycle as vinyl is a thermoplastic. Vinyl’s melting point is relatively low which means less energy is required for reprocessing vinyl than that of other polymers, but this has been the reason it is considered a ‘contaminant’ in other polymer streams as it burns at higher temperatures.

Industry does not see vinyl as a contaminant; we see it as a resource. There is very good reason therefore to implement technologies and systems to separate vinyl early in the kerbside waste sorting process.

Using recycled vinyl in new products replaces the use of virgin vinyl compound and reduces the carbon emissions associated with manufacturing virgin vinyl by about 80-85 percent. This significantly lowers the carbon footprint of new vinyl products.

Local manufacturers of vinyl products have indicated that they have an appetite to increase the use of vinyl recyclate if reliable, continuous sources of recyclate are made available. Signatory companies to the long-established PVC Stewardship Program are publicly committed to use recyclate in the products they supply to the market unless product standards prohibit it.

The Council therefore welcomes emerging initiatives by MRFs to separate rigid vinyl packaging and some other flexibles for local reprocessing and reuse in Australia.

VersrTile: recycling vinyl coated farbrics

In 2018, the Victorian state’s Metropolitan Waste and Resource Recovery Group (MWRRG) provided a $20,000 grant to part fund an investigation into the feasibility of recycling vinyl coated fabrics into roof tiles, one of the product concepts identified in Porject ReMake. The VersrTile project enabled an expert multidisciplinary team led by the Vinyl Council to design and test reprocessing techniques and form prototype roof tiles made from waste billboard skins. The project outcomes included testing the manufactured sample tiles, which found the tiles could resist weathering as required under applicable standards; however, further development is required on the tile prototypes to meet mechanical strength tests required for roof tiles.

A preliminary business case has been developed to understand the financial and production factors that will be required to manufacture these roof tiles economically and to assess their commercially feasibility. The significance of this project is that it identifies a potential reuse of a composite material into a durable, high volume product without the need to separate the polyester fibre from the vinyl.

Read our report VersrTile: Vinyl-Coated Fabric to Roof Tile Recycling Project (2018) here.

Research paper on vinyl banner recycling published

A paper by one of the Vinyl Council's research partners, Dr. Sagar T Cholake, Research Associate, Centre for Sustainable Materials Research & Technology, University of New South Wales, has been published in the journal Resources, Conservation and Recycling Volume 136, September 2018 related to the Council's vinyl banner recycling project.

The paper, ‘Cost-effective and sustainable approach to transform end-of-life vinyl banner to value added product’ details a potential, new low-cost solution for waste PVC coated fabrics that does not require the separation of the PVC from the polyester fabric, overcoming a major barrier to recycling.

Testing by the UNSW team indicated that waste PVC-coated banners could be used to fabricate strong and durable composite panels for multiple indoor and outdoor applications and the paper shows one example of final product.

Life cycle analysis, conducted as part of the research, showed that replacing virgin PVC by recycled PVC from banner emits 78% less greenhouse gas emissions (kg CO2 equivalent).

Access this paper through the online journal here.

New recycling strategy for PVC in Australia

The Vinyl Council has updated its industry strategy aimed at facilitating growth in sustainable PVC recycling practices in Australia.

Developed through consultations with members, industry and government, and at the PVC ReSource Summit held in late 2015, the strategy will direct future actions of the Vinyl Council and the sector.

PVC - the third most commonly used polymer in Australia - is recyclable, however, results show that only low volumes of PVC wastes are recovered, largely because most PVC is used in durable products, and less in packaging (which is where most waste and recycling policies and resources are focussed).

The VCA estimates around 66,900 tonnes ofrecyclablePVC product goes to landfill each year. This is wasted material that could be reprocessed into new quality product by Australian workers and firms, improving Australian productivity, economy and the environment.

The VCA and its members are committed to advancing PVC recycling and reprocessing. The updated industry strategy aims to address barriers, to share knowledge, data and expertise and to encourage innovation of reprocessing, product design and recycling capability.

Key elements in the 2016 Strategy

There are six parts to the strategy and three especially form the foundation:

- Data and information. More data and knowledge are required for effective recycling of PVC.

- Collaboration between willing partners to drive change. Systemic change requires partners working together, and strong PVC reprocessing capability is required in all key States.

- End markets, without which there is no viable recycling practice. This requires building connections between demand and supply, development of appropriate recyclate-absorbing products and encouraging substitution of virgin or other less sustainable materials.

The VCA has established successful vinyl recylcing programs including the PVC Recycling in Hospitals program which is now in place at over 60 Australian hospitlas. The VCA thanks all those who contribute to the success of PVC recycling in Australia and looks forward to working with many to achieve the actions for improved results for Australia's recycling rate, productivity and manufacturing future.

For more detail on the Strategy contact the Vinyl Council's This email address is being protected from spambots. You need JavaScript enabled to view it..