Vinyl Council of Australia’s PVC Recycling in Hospitals program expands in regional areas

The start of 2022 has seen PVC recycling in healthcare expanding to more regional areas of Australia, including Albany in WA and Rockhampton in QLD, with more than 280 hospitals currently participating in the Vinyl Council of Australia’s initiated program.

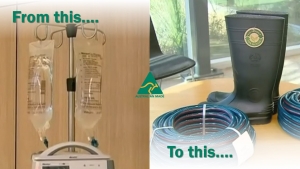

Single-use plastics play a vital, life-saving role in healthcare, such as intravenous fluid bags, oxygen masks and tubing. Their ability to be recycled, through schemes like the PVC Recycling in Hospitals program, is diverting increasing volumes of this high-quality, medical grade material from landfill for recycling back into new, useful products. Since 2015, the program has recycled over 545 tonnes of these products – equivalent to over 27 million IV bags.

Despite the impact of the Covid-19 pandemic reducing elective surgery in most states and causing program suspensions in Tasmania, participation in the PVC Recycling in Hospitals program has grown nationally. The latest data shows that over the last two years, more than 60 hospitals Australia-wide have signed up.

Although 2021 waste collection volumes (119 tonnes) were slightly down on the 2020 figures (129 tonnes) due to pandemic disruption, the program continues to play an important role as life starts to return to normality.

Launched in 2013, the PVC Recycling in Hospitals Program collects and recycles non-infectious oxygen masks and tubing and Baxter IV fluid bags from theatres, recovery wards, intensive care units, dialysis and day procedure units. The recovered PVC is reused in a variety of new applications from garden hose to new gumboots.

Although 2021 volumes were down on the previous year due to the pandemic, the 119 tonnes collected were equivalent to 5.95 million IV fluid bags. The Vinyl Council, along with program partners Baxter Healthcare and recycler Welvic Australia, have a target for the program of the equivalent of 50 million IV bags recycled within Australia over a five-year period until 2025.

Reducing contamination and increasing collection at existing hospitals by ensuring the program is implemented correctly will be key focus areas in achieving this target. Separating PVC products from non-PVC products where the waste is generated leads to a higher volume of waste being diverted from landfill. It also produces a higher quality of PVC recyclate by minimising contamination from other materials.

Vinyl Council of Australia Chief Executive, Sophi MacMillan comments: “Our program is playing a leading role in lowering the amount of recyclable single-use plastic used in healthcare going into landfill, thereby reducing its environmental impact.

“We are delighted with the program’s progress, despite the challenging times. We thank everyone for their ongoing involvement and enthusiasm for the program.

“The sustained increase in hospital participation and collection efforts in recent months is encouraging. We hope that with rising participation the 50 million target remains in reach and recycling volumes increase back up to pre-Covid levels again throughout early to mid 2022.”

Since its launch, the Vinyl Council of Australia’s successful medical waste recycling program has inspired similar schemes in eight other countries, such as South Africa, Canada, the European VinylPlus PVCMed initiative and RecoMed in the UK. For more information contact 03 9510 1711, email This email address is being protected from spambots. You need JavaScript enabled to view it. or follow @VCAustralia.

Banksia Awards: ‘PVC a good material for a circular economy’

The 2017 Banksia Award Judges have released their assessments of the PVC Recycling in Hospitals Program initiated by the Vinyl Council of Australia.

Describing the scheme as a ‘world first’, the judges praised it as an ‘excellent case study of an industry's response to keeping its social license’ and ‘embracing product stewardship’ as its means to achieve that.

The PVC Recycling in Hospitals Program was one of five Australian finalists for the Circular Economy category at the Awards night in November 2017. While not winning against tough competition in this category, the extremely positive feedback from the judges on our award submission has given the Vinyl Council of Australia team much encouragement to take this successful medical plastic recycling scheme - now operational in more than 120 hospitals in Australia and New Zealand - to even greater heights. The scheme is aiming to recycle a total of 2,500 tonnes per year throughout Australia.

They also commended the ‘good leadership shown by the health industry and good collaboration between industries’, as well as recognising ‘good circularity – PVC is a good material for a circular economy’.

Established in 2009, the program has overcome challenges to divert quality PVC from landfill. Two Vinyl Council members, Baxter Healthcare (multinational and Australian-based manufacturer of IV bags) and Welvic Australia (Australian compounder), collect and recycle IV bags, oxygen masks and oxygen tubing. These are turned into into durable, locally-manufactured products such as industrial and garden hose and children’s playground mats.

Recognising this, the judges stated: “The program stands out as a unique solution taking a waste stream that would historically go to landfill and re-purposing it thus preventing virgin components required for new products.

“The issue of plastics and chemical use in hospitals is enormous and the lack of sustainability focus in that sector is well-known. Seeing a project that brings change to that sort of culture is great. Overall it’s an innovative solution filling a niche that can be expanded globally and sets an example.”

Vinyl Council Chief Executive Sophi MacMillan comments: “We appreciate this valuable feedback and agree completely with the judges’ view that there is much potential to scale this and expand it across other industries. Watch this space!”

PVC Recycling in Hospitals scheme shortlisted for Circular Economy award

The Vinyl Council of Australia’s hugely-successful hospitals’ recycling scheme has been shortlisted in the Circular Economy category of the Banksia Foundation Awards 2017.

From its earliest beginnings in 2009, the scheme has overcome challenges to embrace more than 80 hospitals in Australia and 28 in New Zealand. IV bags, face masks and oxygen tubing are collected and recycled by two Vinyl Council members Baxter (multinational and Australian-based manufacturer of IV bags) and Welvic (Australian compounder).

Significant investment and commitment by these two companies and the Council has helped the PVC Recycling in Hospitals scheme to flourish and divert quality PVC from landfill into durable, locally-manufactured products. These include industrial and garden hose in Australia and children’s playground mats in New Zealand, which are exported to Australia and around the Pacific.

It is also being replicated round the world. For example, in the UK 11 hospitals are participating in the growing RecoMed PVC recycling scheme with high-quality medical grade plastic being recycled into horticultural products.

The Vinyl Council’s PVC Recycling Project Manager, Helen Millicer said: “We are thrilled to have been shortlisted for this sustainability award. In terms of significance, this Australian initiative shows that quality material from hospitals can be safely recovered and reprocessed to become durable, locally-made product in Australia and in other parts of the world.

“There is no limit to the demand for this high-quality material as a substitute for virgin in Australia and New Zealand. It’s a great step forward in terms of sustainability for PVC and the environment. It’s a valuable raw material resource that can be given a useful ‘second life’ in new products and that’s good news all round!”

The scheme is aiming to recycle a total of 2,500 tonnes per year throughout Australia. Currently, monthly PVC quantities from both hospitals and home patients (Australia & New Zealand) produces enough for 95 km of garden hose or 4500 cushioned play mats for children’s playgrounds. This displaces 14 tonnes a month of imported PVC resin and additives, and reduces greenhouse gas emissions associated with the PVC in new products by 80 percent.

Winners will be announced at the Banksia Awards ceremony in Sydney on 1 November.

New recycling strategy for PVC in Australia

The Vinyl Council has updated its industry strategy aimed at facilitating growth in sustainable PVC recycling practices in Australia.

Developed through consultations with members, industry and government, and at the PVC ReSource Summit held in late 2015, the strategy will direct future actions of the Vinyl Council and the sector.

PVC - the third most commonly used polymer in Australia - is recyclable, however, results show that only low volumes of PVC wastes are recovered, largely because most PVC is used in durable products, and less in packaging (which is where most waste and recycling policies and resources are focussed).

The VCA estimates around 66,900 tonnes ofrecyclablePVC product goes to landfill each year. This is wasted material that could be reprocessed into new quality product by Australian workers and firms, improving Australian productivity, economy and the environment.

The VCA and its members are committed to advancing PVC recycling and reprocessing. The updated industry strategy aims to address barriers, to share knowledge, data and expertise and to encourage innovation of reprocessing, product design and recycling capability.

Key elements in the 2016 Strategy

There are six parts to the strategy and three especially form the foundation:

- Data and information. More data and knowledge are required for effective recycling of PVC.

- Collaboration between willing partners to drive change. Systemic change requires partners working together, and strong PVC reprocessing capability is required in all key States.

- End markets, without which there is no viable recycling practice. This requires building connections between demand and supply, development of appropriate recyclate-absorbing products and encouraging substitution of virgin or other less sustainable materials.

The VCA has established successful vinyl recylcing programs including the PVC Recycling in Hospitals program which is now in place at over 60 Australian hospitlas. The VCA thanks all those who contribute to the success of PVC recycling in Australia and looks forward to working with many to achieve the actions for improved results for Australia's recycling rate, productivity and manufacturing future.

For more detail on the Strategy contact the Vinyl Council's This email address is being protected from spambots. You need JavaScript enabled to view it..